Agriculture

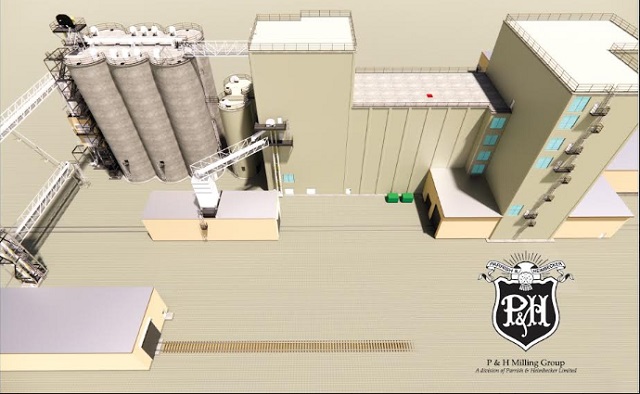

P&H Group building $241-million flour milling facility in Red Deer County.

P&H Milling Group has qualified for the Agri-Processing Investment Tax Credit program

Alberta’s food processing sector is the second-largest manufacturing industry in the province and the flour milling industry plays an important role within the sector, generating millions in annual economic impact and creating thousands of jobs. As Canada’s population continues to increase, demand for high-quality wheat flour products is expected to rise. With Alberta farmers growing about one-third of Canada’s wheat crops, the province is well-positioned to help meet this demand.

Alberta’s Agri-Processing Investment Tax Credit program is supporting this growing sector by helping to attract a new wheat flour milling business to Red Deer County. P&H Milling Group, a division of Parrish & Heimbecker, Limited, is constructing a $241-million facility in the hamlet of Springbrook to mill about 750 metric tonnes of wheat from western Canadian farmers into flour, every single day. The new facility will complement the company’s wheat and durum milling operation in Lethbridge.

“P&H Milling Group’s new flour mill project is proof our Agri-Processing Investment Tax Credit program is doing its job to attract large-scale investments in value-added agricultural manufacturing. With incentives like the ag tax credit, we’re providing the right conditions for processors to invest in Alberta, expand their business and help stimulate our economy.”

P&H Milling Group’s project is expected to create about 27 permanent and 200 temporary jobs. Byproducts from the milling process will be sold to the livestock feed industry across Canada to create products for cattle, poultry, swine, bison, goats and fish. The new facility will also have capacity to add two more flour mills as demand for product increases in the future.

“This new facility not only strengthens our position in the Canadian milling industry, but also boostsAlberta’s baking industry by supplying high-quality flour to a diverse range of customers. We are proud to contribute to the local economy and support the agricultural community by sourcing 230,000 metric tonnes of locally grown wheat each year.”

To be considered for the tax credit program, corporations must invest at least $10 million in a project to build or expand a value-added agri-processing facility in Alberta. The program offers a 12 per cent non-refundable tax credit based on eligible capital expenditures. Through this program, Alberta’s government has granted P&H Milling Group conditional approval for a tax credit estimated at $27.3 million.

“We are grateful P&H Milling Group chose to build here in Red Deer County. This partnership willbolster our local economy and showcase our prime centralized location in Alberta, an advantage that facilitates efficient operations and distribution.”

Quick facts

- In 2023, Alberta’s food processing sector generated $24.3 billion in sales, making it the province’s second-largest manufacturing industry, behind petroleum and coal.

- That same year, just over three million metric tonnes of milled wheat and more than 2.3 million metric tonnes of wheat flour was manufactured in Canada.

- Alberta’s milled wheat and meslin flour exports increased from $8.6 million in 2019 to $19.8 million in 2023, a 130.2 per cent increase.

- Demand for flour products rose in Alberta from 2019 to 2022, with retail sales increasing by 24 per cent during that period.

- Alberta’s flour milling industry generated about $840.7 million in economic impact and created more than 2,200 jobs on average between 2018 and 2021.

- Alberta farmers produced 9.3 million metric tonnes of wheat in 2023, representing 29.2 per cent of total Canadian production.

Related information

Agriculture

End Supply Management—For the Sake of Canadian Consumers

This is a special preview article from the:

U.S. President Donald Trump’s trade policy is often chaotic and punitive. But on one point, he is right: Canada’s agricultural supply management system has to go. Not because it is unfair to the United States, though it clearly is, but because it punishes Canadians. Supply management is a government-enforced price-fixing scheme that limits consumer choice, inflates grocery bills, wastes food, and shields a small, politically powerful group of producers from competition—at the direct expense of millions of households.

And yet Ottawa continues to support this socialist shakedown. Last week, Prime Minister Mark Carney told reporters supply management was “not on the table” in negotiations for a renewed United States-Mexico-Canada Trade Agreement, despite U.S. negotiators citing it as a roadblock to a new deal.

Supply management relies on a web of production quotas, fixed farmgate prices, strict import limits, and punitive tariffs that can approach 300 percent. Bureaucrats decide how much milk, chicken, eggs, and poultry Canadians farmers produce and which farmers can produce how much. When officials misjudge demand—as they recently did with chicken and eggs—farmers are legally barred from responding. The result is predictable: shortages, soaring prices, and frustrated consumers staring at emptier shelves and higher bills.

This is not a theoretical problem. Canada’s most recent chicken production cycle, ending in May 2025, produced one of the worst supply shortfalls in decades. Demand rose unexpectedly, but quotas froze supply in place. Canadian farmers could not increase production. Instead, consumers paid more for scarce domestic poultry while last-minute imports filled the gap at premium prices. Eggs followed a similar pattern, with shortages triggering a convoluted “allocation” system that opened the door to massive foreign imports rather than empowering Canadian farmers to respond.

Over a century of global experience has shown that central economic planning fails. Governments are simply not good at “matching” supply with demand. There is no reason to believe Ottawa’s attempts to manage a handful of food categories should fare any better. And yet supply management persists, even as its costs mount.

Those costs fall squarely on consumers. According to a Fraser Institute estimate, supply management adds roughly $375 a year to the average Canadian household’s grocery bill. Because lower-income families spend a much higher proportion of their income on food, the burden falls most heavily on them.

The system also strangles consumer choice. European countries produce thousands of varieties of high-quality cheeses at prices far below what Canadians pay for largely industrial domestic products. But our import quotas are tiny, and anything above them is hit with tariffs exceeding 245 percent. As a result, imported cheeses can cost $60 per kilogram or more in Canadian grocery stores. In Switzerland, one of the world’s most eye-poppingly expensive countries, where a thimble-sized coffee will set you back $9, premium cheeses are barely half the price you’ll find at Loblaw or Safeway.

Canada’s supply-managed farmers defend their monopoly by insisting it provides a “fair return” for famers, guarantees Canadians have access to “homegrown food” and assures the “right amount of food is produced to meet Canadian needs.” Is there a shred of evidence Canadians are being denied the “right amount” of bread, tuna, asparagus or applesauce? Of course not; the market readily supplies all these and many thousands of other non-supply-managed foods.

Like all price-fixing systems, Canada’s supply management provides only the illusion of stability and security. We’ve seen above what happens when production falls short. But perversely, if a farmer manages to get more milk out of his cows than his quota, there’s no reward: the excess must be

dumped. Last year alone, enough milk was discarded to feed 4.2 million people.

Over time, supply management has become less about farming and more about quota ownership. Artificial scarcity has turned quotas into highly valuable assets, locking out young farmers and rewarding incumbents.

Why does such a dysfunctional system persist? The answer is politics. Supply management is of outsized importance in Quebec, where producers hold a disproportionate share of quotas and are numerous enough to swing election results in key ridings. Federal parties of all stripes have learned the cost of crossing this lobby. That political cowardice now collides with reality. The USMCA is heading toward mandatory renegotiation, and supply management is squarely in Washington’s sights. Canada depends on tariff-free access to the U.S. market for hundreds of billions of dollars in exports. Trading away a deeply-flawed system to secure that access would make economic sense.

Instead, Ottawa has doubled down. Not just with Carney’s remarks last week but with Bill C-202, which makes it illegal for Canadian ministers to reduce tariffs or expand quotas on supply-managed goods in future trade talks. Formally signalling that Canada’s negotiating position is hostage to a tiny domestic lobby group is reckless, and weakens Canada’s hand before talks even begin.

Food prices continue to rise faster than inflation. Forecasts suggest the average family will spend $1,000 more on groceries next year alone. Supply management is not the only cause, but it remains a major one. Ending it would lower prices, expand choice, reduce waste, and reward entrepreneurial farmers willing to compete.

If Donald Trump can succeed in forcing supply management onto the negotiating table, he will be doing Canadian consumers—and Canadian agriculture—a favour our own political class has long refused to deliver.

The original, full-length version of this article was recently published in C2C Journal. Gwyn Morgan is a retired business leader who was a director of five global corporations.

Agriculture

The Climate Argument Against Livestock Doesn’t Add Up

From the Frontier Centre for Public Policy

Livestock contribute far less to emissions than activists claim, and eliminating them would weaken nutrition, resilience and food security

The war on livestock pushed by Net Zero ideologues is not environmental science; it’s a dangerous, misguided campaign that threatens global food security.

The priests of Net Zero 2050 have declared war on the cow, the pig and the chicken. From glass towers in London, Brussels and Ottawa, they argue that cutting animal protein, shrinking herds and pushing people toward lentils and lab-grown alternatives will save the climate from a steer’s burp.

This is not science. It is an urban belief that billions of people can be pushed toward a diet promoted by some policymakers who have never worked a field or heard a rooster at dawn. Eliminating or sharply reducing livestock would destabilize food systems and increase global hunger. In Canada, livestock account for about three per cent of total greenhouse gas emissions, according to Environment and Climate Change Canada.

Activists speak as if livestock suddenly appeared in the last century, belching fossil carbon into the air. In reality, the relationship between humans and the animals we raise is older than agriculture. It is part of how our species developed.

Two million years ago, early humans ate meat and marrow, mastered fire and developed larger brains. The expensive-tissue hypothesis, a theory that explains how early humans traded gut size for brain growth, is not ideology; it is basic anthropology. Animal fat and protein helped build the human brain and the societies that followed.

Domestication deepened that relationship. When humans raised cattle, sheep, pigs and chickens, we created a long partnership that shaped both species. Wolves became dogs. Aurochs, the wild ancestors of modern cattle, became domesticated animals. Junglefowl became chickens that could lay eggs reliably. These animals lived with us because it increased their chances of survival.

In return, they received protection, veterinary care and steady food during drought and winter. More than 70,000 Canadian farms raise cattle, hogs, poultry or sheep, supporting hundreds of thousands of jobs across the supply chain.

Livestock also protected people from climate extremes. When crops failed, grasslands still produced forage, and herds converted that into food. During the Little Ice Age, millions in Europe starved because grain crops collapsed. Pastoral communities, which lived from herding livestock rather than crops, survived because their herds could still graze. Removing livestock would offer little climate benefit, yet it would eliminate one of humanity’s most reliable protections against environmental shocks.

Today, a Maasai child in Kenya or northern Tanzania drinking milk from a cow grazing on dry land has a steadier food source than a vegan in a Berlin apartment relying on global shipping. Modern genetics and nutrition have pushed this relationship further. For the first time, the poorest billion people have access to complete protein and key nutrients such as iron, zinc, B12 and retinol, a form of vitamin A, that plants cannot supply without industrial processing or fortification. Canada also imports significant volumes of soy-based and other plant-protein products, making many urban vegan diets more dependent on long-distance supply chains than people assume. The war on livestock is not a war on carbon; it is a war on the most successful anti-poverty tool ever created.

And what about the animals? Remove humans tomorrow and most commercial chickens would die of exposure, merino sheep would overheat under their own wool and dairy cattle would suffer from untreated mastitis (a bacterial infection of the udder). These species are fully domesticated. Without us, they would disappear.

Net Zero 2050 is a climate target adopted by federal and provincial governments, but debates continue over whether it requires reducing livestock herds or simply improving farm practices. Net Zero advocates look at a pasture and see methane. Farmers see land producing food from nothing more than sunlight, rain and grass.

So the question is not technical. It is about how we see ourselves. Does the Net Zero vision treat humans as part of the natural world, or as a threat that must be contained by forcing diets and erasing long-standing food systems? Eliminating livestock sends the message that human presence itself is an environmental problem, not a participant in a functioning ecosystem.

The cow is not the enemy of the planet. Pasture is not a problem to fix. It is a solution our ancestors discovered long before anyone used the word “sustainable.” We abandon it at our peril and at theirs.

Dr. Joseph Fournier is a senior fellow at the Frontier Centre for Public Policy. An accomplished scientist and former energy executive, he holds graduate training in chemical physics and has written more than 100 articles on energy, environment and climate science.

-

Agriculture23 hours ago

Agriculture23 hours agoEnd Supply Management—For the Sake of Canadian Consumers

-

Digital ID21 hours ago

Digital ID21 hours agoCanadian government launches trial version of digital ID for certain licenses, permits

-

Alberta20 hours ago

Alberta20 hours agoAlberta Next Panel calls to reform how Canada works

-

Business18 hours ago

Business18 hours agoThe “Disruptor-in-Chief” places Canada in the crosshairs

-

International15 hours ago

International15 hours agoGeorgia county admits illegally certifying 315k ballots in 2020 presidential election

-

Artificial Intelligence19 hours ago

Artificial Intelligence19 hours agoUK Police Pilot AI System to Track “Suspicious” Driver Journeys

-

Energy14 hours ago

Energy14 hours ago‘The electric story is over’

-

International22 hours ago

International22 hours agoWorld-leading biochemist debunks evolutionary theory