Automotive

‘Net-zero’ targets neither feasible nor realistic

From the Fraser Institute

By Vaclav Smil and Elmira Aliakbari

Canada and other developed countries have committed to achieving “net-zero” carbon emissions by 2050. Yet here at the midway point between the 1997 Kyoto Protocol, the first international treaty to set binding targets for cutting greenhouse gas emissions, and the looming deadline of 2050, recent findings cast doubt on the feasibility of this ambitious transition.

According to a new study published by the Fraser Institute, despite international agreements, significant government spending and regulations, and some technological progress, the world’s dependence on fossil fuels has been steadily and significantly increasing over the past three decades. By 2023, global fossil fuel consumption was 55 per cent higher than in 1997. The share of fossil fuels in global energy consumption has only slightly decreased, dropping from nearly 86 per cent in 1997 to approximately 82 per cent in 2022.

Viewed through a historical lens, this sluggish pace of change is not surprising. The first global energy transition, from traditional biomass fuels (wood, charcoal, straw) to fossil fuels, started more than two centuries ago and unfolded gradually. Coal only surpassed global wood consumption in 1900; crude oil surpassed coal only in the mid-1960s; and natural gas has yet to surpass crude oil. Even today, this transition remains incomplete, as billions of people still rely on traditional biomass energy for cooking and heating.

The scale of the energy transition ahead is daunting. The 19th-century transition from wood to coal and hydrocarbons replaced about 1.5 billion tons of wood, equivalent to 30 exajoules. But the current transition will require at least 400 exajoules of new non-carbon energies by 2050. To put this in a Canadian perspective, generating this amount of clean energy worldwide would require the equivalent of about 22,000 projects the size of British Columbia’s Site C or Newfoundland and Labrador’s Muskrat Falls.

Advocates for today’s mandated energy transition often overlook the complexity of energy transitions and their many challenges. Critical industries such as cement, primary iron, plastics and ammonia still rely heavily on fossil fuels, with no viable alternatives readily available for large-scale adoption.

The energy transition also imposes unprecedented demands for minerals vital for renewable energy technologies, such as copper and lithium, which require substantial time to mine and develop. According to the International Energy Agency, the widespread adoption of electric vehicles by 2040 will require more than 40 times more lithium and up to 25 times more cobalt, nickel and graphite than the world was producing in 2020. Assuming such scale is even possible, there are serious questions about whether mineral and metal production can expand nearly quickly enough to meet the 2050 deadline.

Transitioning to a net-zero carbon footprint also requires a massive overhaul of existing energy infrastructure, as well as development of new systems and technologies, all of which will be very costly. High-income countries (including Canada) would need to allocate between 20 and 25 per cent of their annual incomes (broadly measured as GDP) to the transition. That would create significant economic challenges for citizens in terms of living standards.

A final problem is that achieving decarbonization by 2050 hinges on extensive and sustained global cooperation, a difficult task given the conflicting political, strategic and economic interests of different countries. In 2024 it’s not easy to imagine how the major countries can coordinate their decarbonization efforts. The European Union and the United States are already reducing emissions. But China and India are still increasing their coal combustion and have decades of emissions growth ahead of them, while Russia’s economic stability depends on exporting fossil fuels. And low-income African countries are expanding their fossil fuel consumption to build infrastructure and lift their living standards to alleviate poverty.

After two centuries of rising global carbon emissions, the goal of zero carbon by 2050 faces significant economic, political and practical obstacles. Severing modern civilization’s reliance on fossil fuels may be a desirable long-term goal but it simply cannot be accomplished either rapidly or inexpensively.

Authors:

Automotive

Canadians’ Interest in Buying an EV Falls for Third Year in a Row

From Energy Now

Electric vehicle prices fell 7.8 per cent in the last quarter of 2024 year-over-year, according to the AutoTader price index

Fewer Canadians are considering buying an electric vehicle, marking the third year in a row interest has dropped despite lower EV prices, a survey from AutoTrader shows.

Forty-two per cent of survey respondents say they’re considering an EV as their next vehicle, down from 46 per cent last year. In 2022, 68 per cent said they would consider buying an EV.

Meanwhile, 29 per cent of respondents say they would exclusively consider buying an EV — a significant drop from 40 per cent last year.

The report, which surveyed 1,801 people on the AutoTrader website, shows drivers are concerned about reduced government incentives, a lack of infrastructure and long-term costs despite falling prices.

Electric vehicle prices fell 7.8 per cent in the last quarter of 2024 year-over-year, according to the AutoTader price index.

The survey, conducted between Feb. 13 and March 12, shows 68 per cent of non-EV owners say government incentives could influence their decision, while a little over half say incentives increase their confidence in buying an EV.

Automotive

Hyundai moves SUV production to U.S.

MxM News

MxM News

Quick Hit:

Hyundai is responding swiftly to 47th President Donald Trump’s newly implemented auto tariffs by shifting key vehicle production from Mexico to the U.S. The automaker, heavily reliant on the American market, has formed a specialized task force and committed billions to American manufacturing, highlighting how Trump’s America First economic policies are already impacting global business decisions.

Key Details:

-

Hyundai has created a tariffs task force and is relocating Tucson SUV production from Mexico to Alabama.

-

Despite a 25% tariff on car imports that began April 3, Hyundai reported a 2% gain in Q1 operating profit and maintained earnings guidance.

-

Hyundai and Kia derive one-third of their global sales from the U.S., where two-thirds of their vehicles are imported.

Diving Deeper:

In a direct response to President Trump’s decisive new tariffs on imported automobiles, Hyundai announced Thursday it has mobilized a specialized task force to mitigate the financial impact of the new trade policy and confirmed production shifts of one of its top-selling models to the United States. The move underscores the gravity of the new 25% import tax and the economic leverage wielded by a White House that is now unambiguously prioritizing American industry.

Starting with its popular Tucson SUV, Hyundai is transitioning some manufacturing from Mexico to its Alabama facility. Additional consideration is being given to relocating production away from Seoul for other U.S.-bound vehicles, signaling that the company is bracing for the long-term implications of Trump’s tariffs.

This move comes as the 25% import tax on vehicles went into effect April 3, with a matching tariff on auto parts scheduled to hit May 3. Hyundai, which generates a full third of its global revenue from American consumers, knows it can’t afford to delay action. Notably, U.S. retail sales for Hyundai jumped 11% last quarter, as car buyers rushed to purchase vehicles before prices inevitably climb due to the tariff.

Despite the trade policy, Hyundai reported a 2% uptick in first-quarter operating profit and reaffirmed its earnings projections, indicating confidence in its ability to adapt. Yet the company isn’t taking chances. Ahead of the tariffs, Hyundai stockpiled over three months of inventory in U.S. markets, hoping to blunt the initial shock of the increased import costs.

In a significant show of good faith and commitment to U.S. manufacturing, Hyundai last month pledged a massive $21 billion investment into its new Georgia plant. That announcement was made during a visit to the White House, just days before President Trump unveiled the auto tariff policy — a strategic alignment with a pro-growth, pro-America agenda.

Still, the challenges are substantial. The global auto industry depends on complex, multi-country supply chains, and analysts warn that tariffs will force production costs higher. Hyundai is holding the line on pricing for now, promising to keep current model prices stable through June 2. After that, however, price adjustments are on the table, potentially passing the burden to consumers.

South Korea, which remains one of the largest exporters of automobiles to the U.S., is not standing idle. A South Korean delegation is scheduled to meet with U.S. trade officials in Washington Thursday, marking the start of negotiations that could redefine the two nations’ trade dynamics.

President Trump’s actions represent a sharp pivot from the era of global corporatism that defined trade under the Obama-Biden administration. Hyundai’s swift response proves that when the U.S. government puts its market power to work, foreign companies will move mountains — or at least entire assembly lines — to stay in the game.

-

Business2 days ago

Business2 days agoIs Government Inflation Reporting Accurate?

-

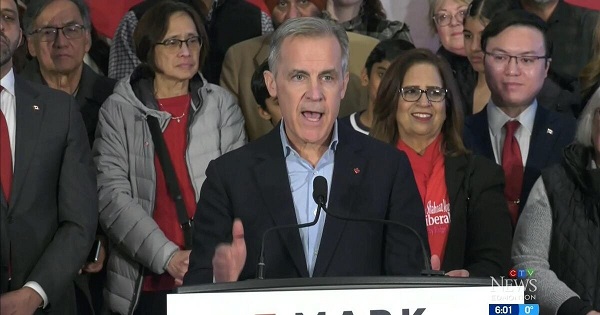

2025 Federal Election2 days ago

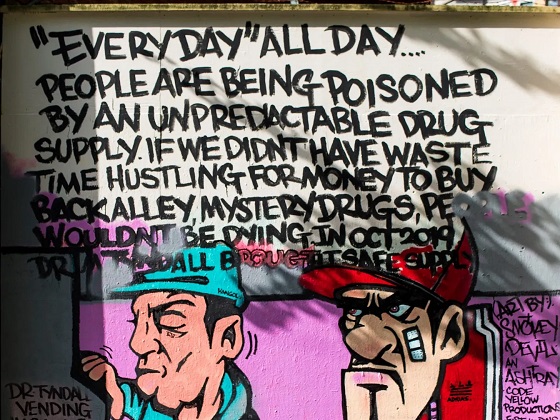

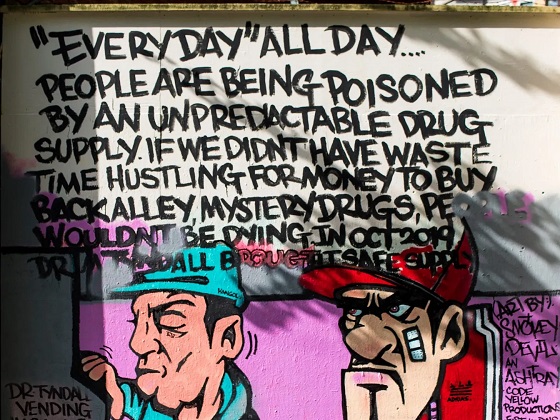

2025 Federal Election2 days agoStudy links B.C.’s drug policies to more overdoses, but researchers urge caution

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoPolls say Canadians will give Trump what he wants, a Carney victory.

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoPoilievre’s Conservatives promise to repeal policy allowing male criminals in female jails

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoCarney Liberals pledge to follow ‘gender-based goals analysis’ in all government policy

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoTrump Has Driven Canadians Crazy. This Is How Crazy.

-

Entertainment1 day ago

Entertainment1 day agoPedro Pascal launches attack on J.K. Rowling over biological sex views

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoThe Anhui Convergence: Chinese United Front Network Surfaces in Australian and Canadian Elections