Canadian Energy Centre

Hubs are the future of carbon capture and storage: Why Alberta is an ideal place to make it happen

From the Canadian Energy Centre

Alberta Carbon Trunk Line a ‘perfect example’ of a successful carbon capture and storage hub in action

Call it a CCS highway – a shared transportation and storage network that enables multiple industrial users to reduce emissions faster.

So-called “hubs” or networks are becoming the leading development strategy for carbon capture and storage (CCS) as the world moves faster to fight climate change, according to the Global CCS Institute.

Alberta, with its large industrial operations and more CO2 storage capacity than Norway, Korea, India, and double the entire Middle East, is an early leader in CCS hub development.

“For Alberta, the concept of CCS hubs makes a lot of sense because you have many industry players that are trying to reduce their emissions, paired with beautiful geological opportunities beneath,” says Beth (Hardy) Valiaho, vice-president with the International CCS Knowledge Centre in Regina, Saskatchewan.

Jarad Daniels, CEO of the Melbourne, Australia-based Global CCS Institute, says that historically, CCS would be a single project integrating a CO2 capture plant with dedicated CO2 compression, pipeline and storage systems.

“Networks, where each entity typically operates only part of the full CCS value chain provide several benefits,” he says.

“They reduce costs and commercial risk by allowing each company to remain focused on their core business.”

The institute, which released its annual global status of CCS report in November, is now tracking more than 100 CCS hubs in development around the world.

Alberta already has one, and Valiaho says it is a “perfect example” of what she likens to on and off-ramps on a CO2 highway.

The Alberta Carbon Trunk Line (ACTL) went into service in 2020 as a shared pipeline taking CO2 captured at two facilities in the Edmonton region to permanent underground storage in a depleted oil field.

So far ACTL has transported more than four million tonnes of CO2 to storage that would have otherwise been emitted to the atmosphere – the equivalent emissions of approximately 900,000 cars.

ACTL was constructed with a “build it and they will come” mentality, Valiaho says. It has enough capacity to transport 14.6 million tonnes of CO2 per year but only uses 1.6 million tonnes of space per year today.

The future-in-mind plan is working. A $1.6 billion net zero hydrogen complex being built by Air Products near Edmonton will have an on-ramp to ACTL when it is up and running later this year.

Air Products will supply hydrogen to a new renewable diesel production plant being built by Imperial Oil. Three million tonnes of CO2 per year are to be captured at the complex and transported for storage by the ACTL Edmonton Connector.

Hub projects like this are important globally, Daniels says, as CCS operations need to dramatically increase from 50 million tonnes of storage per year today to one billion tonnes by 2030 and 10 billion tonnes by 2050.

“It’s clear the development of CCS networks and hubs is critical for achieving the multiple gigatonne levels of deployment all the climate math says is required by mid-century,” he says.

Valiaho says Alberta is an encouraging jurisdiction to develop CCS hubs in part because the government owns the geological pore space where the CO2 is stored, rather than developers having to navigate dealing with multiple resource owners.

“Alberta is a model for the world, and the fact that the government has declared crown ownership of the pore space is very interesting to a lot of international jurisdictions,” she says.

There are 26 CCS storage project proposals under evaluation in Alberta that could be used as shared storage hubs in the future, including the project proposed by the Pathways Alliance of oil sands producers.

If just six of these projects proceed, the Global CCS Institute says they could store a combined 50 million tonnes of CO2 per year, or the equivalent emissions of more than 11 million cars.

Canadian Energy Centre

Saskatchewan Indigenous leaders urging need for access to natural gas

Piapot First Nation near Regina, Saskatchewan. Photo courtesy Piapot First Nation/Facebook

From the Canadian Energy Centre

By Cody Ciona and Deborah Jaremko

“Come to my nation and see how my people are living, and the struggles that they have day to day out here because of the high cost of energy, of electric heat and propane.”

Indigenous communities across Canada need access to natural gas to reduce energy poverty, says a new report by Energy for a Secure Future (ESF).

It’s a serious issue that needs to be addressed, say Indigenous community and business leaders in Saskatchewan.

“We’re here today to implore upon the federal government that we need the installation of natural gas and access to natural gas so that we can have safe and reliable service,” said Guy Lonechild, CEO of the Regina-based First Nations Power Authority, on a March 11 ESF webinar.

Last year, 20 Saskatchewan communities moved a resolution at the Assembly of First Nations’ annual general assembly calling on the federal government to “immediately enhance” First Nations financial supports for “more desirable energy security measures such as natural gas for home heating.”

“We’ve been calling it heat poverty because that’s what it really is…our families are finding that they have to either choose between buying groceries or heating their home,” Chief Christine Longjohn of Sturgeon Lake First Nation said in the ESF report.

“We should be able to live comfortably within our homes. We want to be just like every other homeowner that has that choice to be able to use natural gas.”

At least 333 First Nations communities across Canada are not connected to natural gas utilities, according to the Canada Energy Regulator (CER).

ESF says that while there are many federal programs that help cover the upfront costs of accessing electricity, primarily from renewable sources, there are no comparable ones to support natural gas access.

“Most Canadian and Indigenous communities support actions to address climate change. However, the policy priority of reducing fossil fuel use has had unintended consequences,” the ESF report said.

“Recent funding support has been directed not at improving reliability or affordability of the energy, but rather at sustainability.”

Natural gas costs less than half — or even a quarter — of electricity prices in Alberta, British Columbia, Ontario, Manitoba and Saskatchewan, according to CER data.

“Natural gas is something NRCan [Natural Resources Canada] will not fund. It’s not considered a renewable for them,” said Chief Mark Fox of the Piapot First Nation, located about 50 kilometres northeast of Regina.

“Come to my nation and see how my people are living, and the struggles that they have day to day out here because of the high cost of energy, of electric heat and propane.”

According to ESF, some Indigenous communities compare the challenge of natural gas access to the multiyear effort to raise awareness and, ultimately funding, to address poor water quality and access on reserve.

“Natural gas is the new water,” Lonechild said.

Alberta

The beauty of economic corridors: Inside Alberta’s work to link products with new markets

From the Canadian Energy Centre

Q&A with Devin Dreeshen, Minister of Transport and Economic Corridors

CEC: How have recent developments impacted Alberta’s ability to expand trade routes and access new markets for energy and natural resources?

Dreeshen: With the U.S. trade dispute going on right now, it’s great to see that other provinces and the federal government are taking an interest in our east, west and northern trade routes, something that we in Alberta have been advocating for a long time.

We signed agreements with Saskatchewan and Manitoba to have an economic corridor to stretch across the prairies, as well as a recent agreement with the Northwest Territories to go north. With the leadership of Premier Danielle Smith, she’s been working on a BC, prairie and three northern territories economic corridor agreement with pretty much the entire western and northern block of Canada.

There has been a tremendous amount of work trying to get Alberta products to market and to make sure we can build big projects in Canada again.

CEC: Which infrastructure projects, whether pipeline, rail or port expansions, do you see as the most viable for improving Alberta’s global market access?

Dreeshen: We look at everything. Obviously, pipelines are the safest way to transport oil and gas, but also rail is part of the mix of getting over four million barrels per day to markets around the world.

The beauty of economic corridors is that it’s a swath of land that can have any type of utility in it, whether it be a roadway, railway, pipeline or a utility line. When you have all the environmental permits that are approved in a timely manner, and you have that designated swath of land, it politically de-risks any type of project.

CEC: A key focus of your ministry has been expanding trade corridors, including an agreement with Saskatchewan and Manitoba to explore access to Hudson’s Bay. Is there any interest from industry in developing this corridor further?

Dreeshen: There’s been lots of talk [about] Hudson Bay, a trade corridor with rail and port access. We’ve seen some improvements to go to Churchill, but also an interest in the Nelson River.

We’re starting to see more confidence in the private sector and industry wanting to build these projects. It’s great that governments can get together and work on a common goal to build things here in Canada.

CEC: What is your vision for Alberta’s future as a leader in global trade, and how do economic corridors fit into that strategy?

Dreeshen: Premier Smith has talked about C-69 being repealed by the federal government [and] the reversal of the West Coast tanker ban, which targets Alberta energy going west out of the Pacific.

There’s a lot of work that needs to be done on the federal side. Alberta has been doing a lot of the heavy lifting when it comes to economic corridors.

We’ve asked the federal government if they could develop an economic corridor agency. We want to make sure that the federal government can come to the table, work with provinces [and] work with First Nations across this country to make sure that we can see these projects being built again here in Canada.

-

Also Interesting2 days ago

Also Interesting2 days agoMortgage Mayhem: How Rising Interest Rates Are Squeezing Alberta Homeowners

-

Alberta2 days ago

Alberta2 days agoAlberta takes big step towards shorter wait times and higher quality health care

-

Business2 days ago

Business2 days agoStocks soar after Trump suspends tariffs

-

COVID-192 days ago

COVID-192 days agoBiden Admin concealed report on earliest COVID cases from 2019

-

Business2 days ago

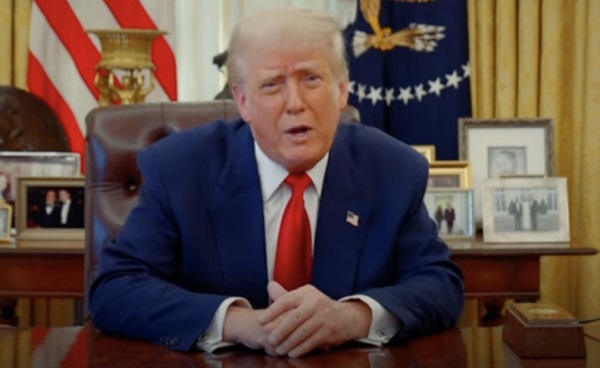

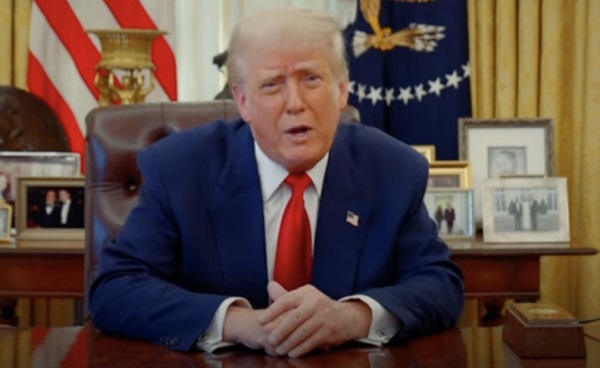

Business2 days agoTrump raises China tariffs to 125%, announces 90-day pause for countries who’ve reached out to negotiate

-

Business2 days ago

Business2 days agoScott Bessent Says Trump’s Goal Was Always To Get Trading Partners To Table After Major Pause Announcement

-

2025 Federal Election1 day ago

2025 Federal Election1 day agoResearchers Link China’s Intelligence and Elite Influence Arms to B.C. Government, Liberal Party, and Trudeau-Appointed Senator

-

Energy2 days ago

Energy2 days agoTrump signs four executive orders promoting coal industry