Automotive

Electric vehicles facing uphill climb

From Resource Works

Ford shifts from EVs to gasoline trucks in Oakville due to declining demand and financial losses, challenging government EV targets.

In October 2020, the federal and Ontario governments announced with fanfare that they would each pour $295 million into helping Ford upgrade its assembly plant in Oakville to start making electric vehicles.

“The upgrade of the Ford plant will make Oakville into the company’s No 1. electric vehicle factory in North America,” we were told.

And Prime Minister Trudeau declared: “This is a win-win. . . . helping accelerate our transition to a low-carbon, clean-growth economy, which will help protect our environment, drive innovation, and create many good middle-class jobs.”

In April 2023, Ford announced it will spend $1.8 billion to retool its Oakville Assembly Complex, beginning in mid-2024, to build next-generation passenger electric vehicles in 2025.

Then the target date of 2025 becomes 2027.

And now, in July 2024, reality strikes: Ford confirmed that the Oakville plant would no longer produce electric three-row SUVs but would instead turn out larger, gasoline-powered versions of its flagship F-Series pickup truck.

The reason: a global slowdown in electric vehicle demand, with hesitant customers delaying plans to buy EVs, and many opting instead for hybrid-electric vehicles.

Ford, for one, said it will step up hybrid offerings and that by 2030 it expects to offer hybrid powertrains across its lineup of gas-powered vehicles. Ford has also delayed production of electric pickup trucks in Tennessee.

Ford now says its electric vehicle unit lost $1.3 billion USD in the first quarter alone. It sold 10,000 vehicles in that period, and thus lost about $132,000 US for every EV it sold.

General Motors also announced it would cut production of EVs, citing slowing demand.

As far as we know, Honda Canada is proceeding with a $15 billion plan to create Canada’s first comprehensive electric-vehicle supply chain, comprising four plants in Ontario. It includes Honda’s first EV assembly plant in Alliston, ON, which Honda said will produce up to 240,000 vehicles per year.

Flavio Volpe, president of the Automotive Parts Manufacturers Association, said the Ford decision is “not good news,” and he fears there will be similar announcements from other car companies.

And automotive industry analyst Robert Karwel says: “I would definitely not be surprised to see announcements from other companies.”

“People are getting payment fatigue right now generally, and EVs are more expensive,” said Karwel, a senior manager of J.D. Power’s Power Information Network. “The average car payment hit $900 a month in January.”

In the first quarter of this year, 46,744 light and medium-duty EVs were registered across Canada, 11.2% of the market share.

B.C. has long led Canada in the uptake of electric vehicles, and in May they made up 10.7% of light-duty vehicle sales.

But another factor weighing on consumers is B.C.’s recent reduction in rebates for electric vehicles.

B.C. reduced rebates to $3,000 for battery, fuel-cell and longer-range plug-in hybrid electric vehicles and $1,500 for shorter-range plug-in hybrid electric vehicles. The previous incentives ranged from $2,500 to $6,000, depending on the kind of car.

And now, only vehicles sold for under $55,000 qualify for the rebates. Previously, the maximum price was $77,000 to qualify. The federal rebate of $5,000 for qualifying vehicles, introduced on May 1, is still available.

If the slowdown in demand continues, it will only help power producers such as B.C. Hydro, which face staggering demand for power, for EVs and for industrial and clean-energy use.

The federal government requires at least 20% of new vehicles sold in Canada to be zero-emission vehicles (ZEVs) by 2026, at least 60% by 2030, and 100% by 2035. (ZEVs include battery electric vehicles and plug-in hybrid electric vehicles.)

Prime Minister Trudeau: “As a great Canadian once said, that is where the puck is going and that is where we’re going to be.”

B.C. is even more ambitious: It has set targets requiring 90% of all light-duty new vehicle sales to be zero-emission by 2030 and 100% by 2035.

That means B.C. needs substantially more power to cope with EVs — and will require even more than that to handle expected population growth and the province’s plans to electrify BC’s economy and push clean energy.

Now the Energy Futures Institute (EFI) calls in a new report for “a dramatic increase in domestic electricity production” in B.C., and cancellation of current plans to wind down some existing power-generation facilities.

EFI chair Barry Penner: “After years without new generation coming online, the long-awaited Site C dam is expected to start producing power by next year. Even if Site C was available last year or this year, it wouldn’t be enough to avoid having to import electricity from the United States and Alberta to keep our lights on.”

As for the federal target, the Public Policy Forum says Canada must build more electricity generation in the next 25 years than it has over the last century in order to support a net-zero emissions economy by 2050.

All in all, Canada’s electric vehicle transition could cost more than $300 billion by 2040 as the installation of charging infrastructure expands, upgrades to the electrical grid are made, and other changes take place, according to a report released by Natural Resources Canada.

Among other things, it says Canada needs to add 40,000 public charging ports per year on average between now and 2040. There now are around 32,000 public ports across the country, and roughly 11,000 were installed in 2023.

The Canadian Vehicle Manufacturers’ Association says lack of charging infrastructure is already deterring some would-be EV buyers. A lack of charging station availability was cited as a top concern by 72% of consumers, according to an Autotrader Canada survey conducted in March.

- Cornelius van Kooten, an economics professor and Canada Research Chair in Environmental Studies and Climate Change at the University of Victoria, said the federal timeline for electric vehicles “isn’t realistic or feasible.”

In a study for the free-enterprise Fraser Institute, he said that to meet the goal, Canada would need the equivalent of 10 big new hydro dams (or 13 large natural-gas power plants).

Quebec, for one, has already had to start limiting industrial expansion because it can’t fill all the power needs.

So you can but sigh when you hear of Quebec’s latest plan for electric vehicles: it is moving ahead with regulations that not only mandate EV sales but actually prohibit sales of any internal combustion engines — including plug-in hybrids, from January 1, 2035.

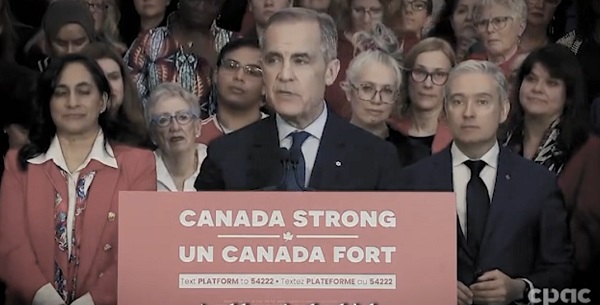

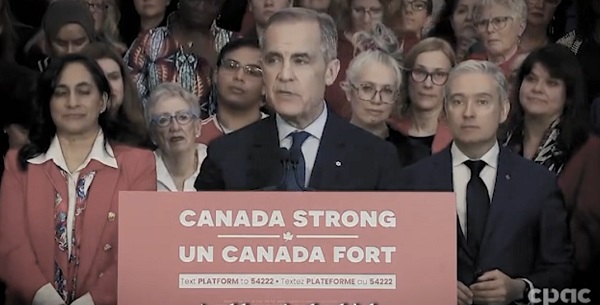

2025 Federal Election

Trudeau and Carney Have Blown $43B on EVs

David Krayden

David Krayden

General Motors laid off 500 workers at his Electric Vehicle (EV) plant in Ingersoll, ON.

It had nothing to do with the tariffs.

It had everything to do with the plummeting fascination that Canadians have for EVs. They are selling like used Edsels in the late 1950s. In a useless attempt to create a demand for these “green” vehicles (which aren’t actually green at all because the production of electricity does not result from magic) the governments of former Prime Minister Justin Trudeau and Ontario Premier Doug Ford wasted $42 billions of your tax money. And it was all to bolster an ideology not a demand for cars. There is no demand for these vehicles.

“You just lost 500 jobs. They’ve nuked those jobs. They’re not there anymore.”

-Dan McTeague

Ford, who saw this coming when he called an early provincial election that he knew he probably was going to lose if he waited for the anticipated vote, was actually honest to reporters when he admitted the layoffs had nothing to do with the dreaded Trump tariff but everything to do with public taste.

“What I understand from the president of General Motors that I spoke to, it’s going to be about 500 employees. Has nothing to do with the tariffs. He said, the volume is not there. People are not purchasing like they thought they would. So, they have thousands of vehicles sitting there. We make sure we support the workers and make sure that we get the government, especially Canada Post, to pick up some of these vehicles, because that’s what it’s geared for you.”

So, Ford expects Canada Post, another government agency on its last legs, to come to the rescue and pick up all these excess EVs? Sounds like it. The irony is that Ford came into office largely because the previous Liberal government had gone hog wild with its green energy program and hydro rates were among the highest in North America. Ford used to say that a industrialized province like Ontario can’t possibly prosper or even subsist on the energy provided by windmills and solar panels. He was right then but over the years he became firmly ensconced in the pocket of Trudeau and the Liberals, just as he is today with Mark Carney.

I spoke to my old friend Dan McTeague on Saturday about this mess. McTeague is a former Liberal MP from the GTA who is the president of Canadians for Affordable Energy today and well known for predicting gas prices across Canada as the @ gaspricewizard on X. As an MP, he always put principal above expediency, and he is no different today. McTeague is anxious for a Conservative Party of Canada (CPC) victory in this federal election and he is actively campaigning for a CPC nominee.

McTeague was not surprised over the dismal outlook for EVs.

“This is about Pierre Poilievre saying your policies are garbage. They’ve hurt Canadians. They’ve undermined the financial feasibility and sustainability of the federal government and the provincial government, and we’re going to get rid of them, just like we’re going to get rid of the CBC.”

-Dan McTeague

“Well, on the 22nd of March after having gone to the Ingersoll plant. I just tweeted a little while ago. I actually went there, filmed what was there in inventory. There were thousands of these vehicles just sitting there doing nothing. Obviously, Doug Ford didn’t get it on the 22nd of March. I said it says a lot about why the Ford nation is giddy about supporting Carney, he’s committed billions in world EV and battery manufacturing like this one in Ingersoll, where the provincial Feds kicked in over half a billion for bright drops. Was supposed to sell 100,000 units. Only sold 2100 actually, it got wrong. It was 2500 they might have probably given that a few away there. But look, this is anticipating what was there. It’s pretty obvious. I mean, I don’t just predict gas prices. Pretty good idea policies, EV mandates, the entire nets,” McTeague said.

McTeague explained that the “EV mandates are toast,” not just because President Donald Trump eliminated them but because they simply never had traction with consumers. He noted that Carney is playing games with the consumer carbon tax – because he hasn’t eliminated it but merely reduced it temporarily to zero – and has continued to keep emissions caps in place.

“Why are they doubling down on forcing us to have California-style appliances, which are extraordinarily costly to consumers. There are thousands of these things that are coming up. GFANZ, the Glasgow Financial Alliance for Net Zero that Mark Carney put forward, is now subject to antitrust review in the United States. This guy could be charged and billions of dollars taken away from the GFANZ organization,” McTeague said, adding that “anybody who hopped on the bandwagon a few years ago on net zero is now looking pretty damn foolish, and it’s amazing to see so many stunned Canadians falling in for this.”

“You just lost 500 jobs. They’ve nuked those jobs. They’re not there anymore.”

The former Liberal MP said the EV program is just one example of a failed economic record from the Trudeau-Carney regime. “However you slice it, the Liberals have had 10 years of failed policies. Net Zero has laid an egg. It’s not doing anything. And what they’re going to try to do is use a lot more public money and hopefully put enough wool over everyone’s eyes, so that we continue to go down this road of more recklessness as a result of what we’ve seen on EVs.

“Anybody who hopped on the bandwagon a few years ago on net zero is now looking pretty damn foolish, and it’s amazing to see so many stunned Canadians falling in for this.”

McTeague also wondered how the Ontario premier has moved from a commonsense politician on green energy to a cheerleader for Trudeau’s environmental authoritarianism. “For Doug Ford to have signed onto this. I mean, Shame on him, but it probably explains why he doesn’t want to support Pierre Poilievre.”

Said McTeague: “This is about Pierre Poilievre saying your policies are garbage. They’ve hurt Canadians. They’ve undermined the financial feasibility and sustainability of the federal government and the provincial government, and we’re going to get rid of them, just like we’re going to get rid of the CBC.”

“And so, for those reasons, you’re going to see why people are not supporting Pierre Poilievre, because they know, you know, they know which side of the bread is going to get buttered and for guys like Doug Ford, Bad mistake, back the wrong horse, and now we’re holding the bag. That’s why he called the election early.”

McTeague said the federal election is a watershed moment for people to decide what kind of future they want: prosperity or poverty. “If Canadians can’t get their head out of the sand and realize that they’re being duped that they can’t afford, you know, the saddling of the debts that these things are incurring for generations to come, and they think that somehow crapping on pipelines or putting emission caps that won’t allow us to make any more oil or gas to send these pipelines that they now suddenly have discovered are important … If we don’t wake up real soon, next two weeks, I can say confidently the next four years is basically cutting people.”

The energy expert predicted that the worst if yet to come if Carney wins a mandate to govern from the voters. “Nothing has changed, if anything, Mr. Carney and his company, as we well know, has lied on so many fronts. And here’s the big one that I’m going to say it here now, because I’ve said it many places before, but to be absolutely clear, you’re going to get a carbon tax, and that 20 cents you think you’re getting off. It’s going to be 40 cents by 2030, likely by the end of another government, “should they form a majority government.”

McTeague cautioned against Canadians becoming deluded and declaring, “Oh, we’re not worried about the future; we just don’t like Donald Trump, and we think Pierre Poilievre is like him.” Give your head a shake — because you know what, I’m going to spend a lot of time over the next few years, pointing back to the stupidity and frivolity of people. And make no mistake, David, these people know what they’re doing. They’re just trying to be cool and friendly because they made mistakes in 2015, 2019 and again in 2021 and they want to somehow think that they can justify bad decisions. What’s coming at the expense of the country? Coming at the expense of our economic sustainability? It’s likely coming at the expense of what concerns me even more so: the future of the federation of this country.”

“I’ve said it many places before, but to be absolutely clear, you’re going to get a carbon tax, and that 20 cents you think you’re getting off. It’s going to be 40 cents by 2030.”

Dan and I also discussed how he has discovered that much of the polling being conducted during this campaign is over-sampling people over 60, which comprise at least 50 percent of the respondents included in the surveys. This bodes well for Poilievre and the Conservatives.

Tomorrow I will be examining how the Consevatives are appealing to working class Canadians, labor union leaders and blue collar workers. Seeking and winning the “hard hat vote” worked for President Richard Nixon in 1972 and President Ronald Reagan in 1984. It can work for Poilevre too in 2025 — and somehow I think he realizes that.

WATCH: The Ugly Truth About Carney: Trudeau Subsidies Fail

CHECK OUT OUR KR NEWS INVESTIGATIVE SERIES ON MARK CARNEY

Rich Banker Man Mark Carney Caught by CBC & CTV Dodging Taxes

Liberal MP Encouraged the Abduction of Conservative Rival for Chinese Bounty

KR NEWSLETTER: Mark Carney to “Fold” “After the vote.” Carney’s Wife’s Eurasia Group Boss Spills the Beans on the Liberals’ “Elbows Up” Master Plan

GFANZ, Mark Carney’s Climate Cabal That Won’t Leave Us Alone

Mark Carney’s is China’s Man

KRN NEWSLETTER: Mark Carney Deep Dive + Disastrous Liberal Leadership Debates

Automotive

Tesla Vandals Keep Running Into The Same Problem … Cameras

From the Daily Caller News Foundation

By Hudson Crozier

People damaging Teslas in anger toward their owners and Elon Musk aren’t picking up on the fact that the vehicles have multiple cameras capable of catching them in the act.

At least nine perpetrators have been caught on video keying, writing graffiti or otherwise defacing Tesla vehicles in parking lots across the U.S. in the month of March alone. Most have led to an arrest or warrant based partly on the footage, which Tesla’s “Sentry Mode” automatically films from the side of the unattended vehicle when it detects human activity nearby.

“Smile, you’re on camera,” Tesla warned in a March 20 X post about its Sentry Mode feature. Musk’s company has been working to upgrade Sentry Mode so that the vehicles will soon blast music at full volume when vandals attack it. The camera system, however, has not stopped an increasing number of vandals from singling out Tesla owners, usually in protest of Musk’s work in the Trump administration for the Department of Government Efficiency (DOGE).

One incident happened on March 29, the same day leftists coordinated protests around the country for a “Global Day of Action” against Musk. That Saturday also saw alleged instances of violence at protests. The demonstrations stemmed from an online call to action by groups such as the Disruption Project, which encourages activists to foment “uprisings,” find a “target’s” home address and other confrontational tactics.

Tesla’s press team did not respond to a request for comment.

One man allegedly caught on camera keying a Tesla SUV on March 24 apologized to the owner who confronted him in a parking lot in Pennsylvania, police and media reports said. The man faces charges of criminal mischief, harassment and disorderly conduct for allegedly carving a swastika onto the vehicle.

“I have nothing against your car, and I have nothing against you,” the suspect said while the owner filmed him in the parking lot. “Obviously, I have something against Elon Musk.” The man called his own behavior “misguided.”

The defendant’s lawyer told Fox News his “client is a proud father, long-time resident, and is currently undergoing cancer treatment” and that he would not comment publicly “pending the outcome of the case.”

One of the most aggressive acts caught by Sentry Mode was in the case of a man who drove an ATV-style vehicle into a Tesla on March 25. Texas police identified the man as Demarqeyun Marquize Cox, arrested him and said he allegedly gave two other nearby Teslas the same treatment while also writing “Elon” on them. The public defender office representing Cox did not respond to a voicemail from the Daily Caller News Foundation.

Tesla cameras also caught three other people in Florida, Texas and Arizona keying and smearing bubble gum on the vehicles in March. The three suspects named by police do not have attorneys listed in county records available for contact.

Many of the vandalism cases since Trump’s return have reportedly caused thousands of dollars in damage for individual owners. For example, the bubble gum incident in Florida brought $2,623.66 in costs, while another keying incident in Minnesota brought $3,200.

Some reported attacks on Tesla vehicles and chargers have gotten the attention of federal law enforcement, including cases of alleged firebombing or shooting.

Two other suspected vandals in New York, one in Minnesota and one in Mississippi have reportedly avoided arrest for now — with one owner declining to press charges — but were all seen on the Teslas’ cameras scratching up the vehicles. Police identified the Mississippi suspect as an illegal migrant from Cuba.

One Tesla owner in North Dakota ridiculed a man who allegedly carved the letter “F” into his Cybertruck in a Costco parking lot — as seen on the Cybertruck’s camera. The defendant faces charges of criminal mischief, and county records say he is representing himself in court.

“I can’t believe this guy is potentially ruining his life to follow a political ideology,” the owner told WDAY News.

“If you’re going to vandalize these vehicles, you’re going to get caught,” the owner said.

-

Alberta1 day ago

Alberta1 day agoProvince to expand services provided by Alberta Sheriffs: New policing option for municipalities

-

Bruce Dowbiggin1 day ago

Bruce Dowbiggin1 day agoIs HNIC Ready For The Winnipeg Jets To Be Canada’s Heroes?

-

2025 Federal Election1 day ago

2025 Federal Election1 day agoCSIS Warned Beijing Would Brand Conservatives as Trumpian. Now Carney’s Campaign Is Doing It.

-

Alberta1 day ago

Alberta1 day agoMade in Alberta! Province makes it easier to support local products with Buy Local program

-

2025 Federal Election1 day ago

2025 Federal Election1 day agoNo Matter The Winner – My Canada Is Gone

-

Health1 day ago

Health1 day agoHorrific and Deadly Effects of Antidepressants

-

2025 Federal Election1 day ago

2025 Federal Election1 day agoCampaign 2025 : The Liberal Costed Platform – Taxpayer Funded Fiction

-

2025 Federal Election1 day ago

2025 Federal Election1 day agoA Perfect Storm of Corruption, Foreign Interference, and National Security Failures