Business

Trans Mountain pipeline’s soaring cost provides more proof of government failure

From the Fraser Institute

By Julio Mejía and Elmira Aliakbari

To recap, since the Trudeau government purchased the project from Kinder Morgan for $4.5 billion in 2018, the cost of the Trans Mountain expansion has ballooned (in nominal terms) to $34 billion.

According to the latest calculations, the Trans Mountain pipeline expansion project, which the Trudeau government purchased from Kinder Morgan in 2018, will cost $3.1 billion more than the $30.9 billion projected last May, bringing the total cost to about $34 billion—more than six times the original estimate.

This is yet another setback for a project facing rising costs and delays. To understand how we arrived at this point, let’s trace the project’s history.

In 2013, Kinder Morgan applied to the National Energy Board (NEB) to essentially twin the existing pipeline built in 1953, which runs for 1,150 kilometres between Strathcona County, Alberta and Burnaby, British Columbia, with the goal to have oil flow through the expansion by December 2019.

In 2016, after three years of deliberations, the NEB approved the pipeline, subject to 157 conditions. By that time, according to Kinder Morgan, costs had risen by $2 billion, bringing the total cost to $7.4 billion.

And yet, despite Kinder Morgan following the legal and regulatory process to get the necessary approvals, the B.C. NDP and Green Party vowed to “immediately employ every tool available” to stop the project. At the same time, the Trudeau government was planning regulations that would increase the cost and uncertainty of infrastructure projects across the country.

Faced with mounting uncertainty and potential setbacks, Kinder Morgan planned to withdraw from the project in 2018. In response, the Trudeau government intervened, nationalizing the project by purchasing it from Kinder Morgan with taxpayer dollars for $4.5 billion. Once under government control, costs skyrocketed to $12.6 billion by 2020 and $21.4 billion by 2022 reportedly due to project safety requirements, financing costs, permitting costs, and crucially, more agreements with Indigenous communities. One year later, in 2023, the Trudeau government said the cost has risen to $30.9 billion.

To recap, since the Trudeau government purchased the project from Kinder Morgan for $4.5 billion in 2018, the cost of the Trans Mountain expansion has ballooned (in nominal terms) to $34 billion.

Surprised? You shouldn’t be.

When government attempts to build infrastructure projects, it often incurs cost overruns and delays due to a lack of incentives to build in an efficient and resourceful way. According to a study by Bent Flyvbjerg, an expert in this field, a staggering 90 per cent of 258 public transportation projects (in 20 countries) exceeded their budgets. The reason behind this phenomenon is clear—unlike private enterprises, government officials can shift cost overruns onto the public without bearing any personal financial consequences.

And the Trudeau government continues to make a bad situation even worse by introducing uncertainty and erecting barriers to private-sector investment in vital infrastructure projects including pipelines. Federal Bill C-69, for instance, overhauled the entire environmental assessment process and imposed complex and subjective review requirements on major energy projects, casting doubt on the viability of future endeavours.

What’s the solution to this mess?

Clearly, if policymakers want to help develop Canada’s natural resource potential—and the jobs, economic opportunity and government revenue that comes with it—they must enact regulatory reform and incentivize private investment. Rather than assuming the role of construction companies, governments should create an environment conducive to private-sector participation, thereby mitigating risk to taxpayers.

By implementing reasonable and competitive regulations that enhance investment incentives, policymakers—including in the Trudeau government—can encourage the private sector to build large-scale infrastructure projects that benefit the Canadian economy.

Authors:

Business

Cuba has lost 24% of it’s population to emigration in the last 4 years

MxM News

MxM News

Quick Hit:

A new study finds Cuba has lost nearly a quarter of its population since 2020, driven by economic collapse and a mass emigration wave unseen outside of war zones. The country’s population now stands at just over 8 million, down from nearly 10 million.

Key Details:

- Independent study estimates Cuba’s population at 8.02 million—down 24% in four years.

- Over 545,000 Cubans left the island in 2024 alone—double the official government figure.

- Demographer warns the crisis mirrors depopulation seen only in wartime, calling it a “systemic collapse.”

Diving Deeper:

Cuba is undergoing a staggering demographic collapse, losing nearly one in four residents over the past four years, according to a new study by economist and demographer Juan Carlos Albizu-Campos. The report estimates that by the end of 2024, Cuba’s population will stand at just over 8 million people—down from nearly 10 million—a 24% drop that Albizu-Campos says is comparable only to what is seen in war-torn nations.

The study, accessed by the Spanish news agency EFE, points to mass emigration as the primary driver. In 2024 alone, 545,011 Cubans are believed to have left the island. That number is more than double what the regime officially acknowledges, as Cuba’s government only counts those heading to the United States, ignoring large flows to destinations like Mexico, Spain, Serbia, and Uruguay.

Albizu-Campos describes the trend as “demographic emptying,” driven by what he calls a “quasi-permanent polycrisis” in Cuba—an interwoven web of political repression, economic freefall, and social decay. For years, Cubans have faced food and medicine shortages, blackout-plagued days, fuel scarcity, soaring inflation, and a broken currency system. The result has been not just migration, but a desperate stampede for the exits.

Yet, the regime continues to minimize the damage. Official figures from the National Office of Statistics and Information (ONEI) put Cuba’s population at just over 10 million in 2023. However, even those numbers acknowledge a shrinking population and the lowest birth rate in decades—confirming the crisis, if not its full scale.

Cuba hasn’t held a census since 2012. The last scheduled one in 2022 has been repeatedly delayed, allegedly due to lack of resources. Experts doubt that any new attempt will be transparent or complete.

Albizu-Campos warns that the government’s refusal to confront the reality of the collapse is obstructing any chance at solutions. More than just a demographic issue, the study describes Cuba’s situation as a “systemic crisis.”

“Havana (Cuba, February 2023)” by Bruno Rijsman licensed under CC BY-SA 2.0 DEED.

Business

Tariff-driven increase of U.S. manufacturing investment would face dearth of workers

From the Fraser Institute

Since 2015, the number of American manufacturing jobs has actually risen modestly. However, as a share of total U.S. employment, manufacturing has dropped from 30 per cent in the 1970s to around 8 per cent in 2024.

Donald Trump has long been convinced that the United States must revitalize its manufacturing sector, having—unwisely, in his view—allowed other countries to sell all manner of foreign-produced manufactured goods in the giant American market. As president, he’s moved quickly to shift the U.S. away from its previous embrace of liberal trade and open markets as cornerstones of its approach to international economic policy —wielding tariffs as his key policy instrument. Since taking office barely two months ago, President Trump has implemented a series of tariff hikes aimed at China and foreign producers of steel and aluminum—important categories of traded manufactured goods—and threatened to impose steep tariffs on most U.S. imports from Canada, Mexico and the European Union. In addition, he’s pledged to levy separate tariffs on imports of automobiles, semi-conductors, lumber, and pharmaceuticals, among other manufactured goods.

In the third week of March, the White House issued a flurry of news releases touting the administration’s commitment to “position the U.S. as a global superpower in manufacturing” and listing substantial new investments planned by multinational enterprises involved in manufacturing. Some of these appear to contemplate relocating manufacturing production in other jurisdictions to the U.S., while others promise new “greenfield” investments in a variety of manufacturing industries.

President Trump’s intense focus on manufacturing is shared by a large slice of America’s political class, spanning both of the main political parties. Yet American manufacturing has hardly withered away in the last few decades. The value of U.S. manufacturing “output” has continued to climb, reaching almost $3 trillion last year (equal to 10 per cent of total GDP). The U.S. still accounts for 15 per cent of global manufacturing production, measured in value-added terms. In fact, among the 10 largest manufacturing countries, it ranks second in manufacturing value-added on a per-capita basis. True, China has become the world’s biggest manufacturing country, representing about 30 per cent of global output. And the heavy reliance of Western economies on China in some segments of manufacturing does give rise to legitimate national security concerns. But the bulk of international trade in manufactured products does not involve goods or technologies that are particularly critical to national security, even if President Trump claims otherwise. Moreover, in the case of the U.S., a majority of two-way trade in manufacturing still takes place with other advanced Western economies (and Mexico).

In the U.S. political arena, much of the debate over manufacturing centres on jobs. And there’s no doubt that employment in the sector has fallen markedly over time, particularly from the early 1990s to the mid-2010s (see table below). Since 2015, the number of American manufacturing jobs has actually risen modestly. However, as a share of total U.S. employment, manufacturing has dropped from 30 per cent in the 1970s to around 8 per cent in 2024.

| U.S. Manufacturing Employment, Select Years (000)* | |

|---|---|

| 1990 | 17,395 |

| 2005 | 14,189 |

| 2010 | 14,444 |

| 2015 | 12,333 |

| 2022 | 12,889 |

| 2024 | 12,760 |

| *December for each year shown. Source: U.S. Bureau of Labor Statistics | |

Economists who have studied the trend conclude that the main factors behind the decline of manufacturing employment include continuous automation, significant gains in productivity across much of the sector, and shifts in aggregate demand and consumption away from goods and toward services. Trade policy has also played a part, notably China’s entry into the World Trade Organization (WTO) in 2001 and the subsequent dramatic expansion of its role in global manufacturing supply chains.

Contrary to what President Trump suggests, manufacturing’s shrinking place in the overall economy is not a uniquely American phenomenon. As Harvard economist Robert Lawrence recently observed “the employment share of manufacturing is declining in mature economies regardless of their overall industrial policy approaches. The trend is apparent both in economies that have adopted free-market policies… and in those with interventionist policies… All of the evidence points to deep and powerful forces that drive the long-term decline in manufacturing’s share of jobs and GDP as countries become richer.”

This brings us back to the president’s seeming determination to rapidly ramp up manufacturing investment and production as a core element of his “America First” program. An important issue overlooked by the administration is where to find the workers to staff a resurgent U.S. manufacturing sector. For while manufacturing has become a notably “capital-intensive” part of the U.S. economy, workers are still needed. And today, it’s hard to see where they will be found. This is especially true given the Trump administration’s well-advertised skepticism about the benefits of immigration.

According to the U.S. Bureau of Labor Statistics, the current unemployment rate across America’s manufacturing industries collectively stands at a record low 2.9 per cent, well below the economy-wide rate of 4.5 per cent. In a recent survey by the National Association of Manufacturers, almost 70 per cent of American manufacturers cited the inability to attract and retain qualified employees as the number one barrier to business growth. A cursory look at the leading industry trade journals confirms that skill and talent shortages remain persistent in many parts of U.S. manufacturing—and that shortages are destined to get worse amid the expected significant jump in manufacturing investment being sought by the Trump administration.

As often seems to be the case with Trump’s stated policy objectives, the math surrounding his manufacturing agenda doesn’t add up. Manufacturing in America is in far better shape than the president acknowledges. And a tariff-driven avalanche of manufacturing investment—should one occur—will soon find the sector reeling from an unprecedented human resource crisis.

Jock Finlayson

Senior Fellow, Fraser Institut

-

Censorship Industrial Complex12 hours ago

Censorship Industrial Complex12 hours agoWelcome to Britain, Where Critical WhatsApp Messages Are a Police Matter

-

Economy2 days ago

Economy2 days agoClearing the Path: Why Canada Needs Energy Corridors to Compete

-

Media17 hours ago

Media17 hours agoTop Five Huge Stories the Media Buried This Week

-

2025 Federal Election17 hours ago

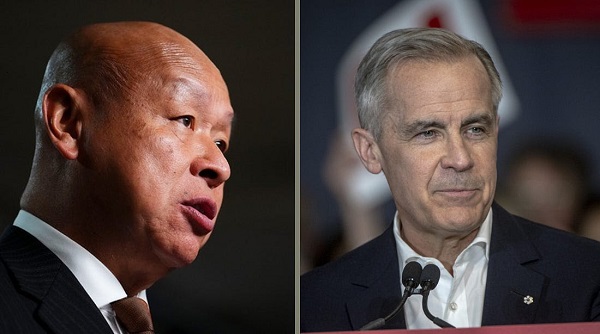

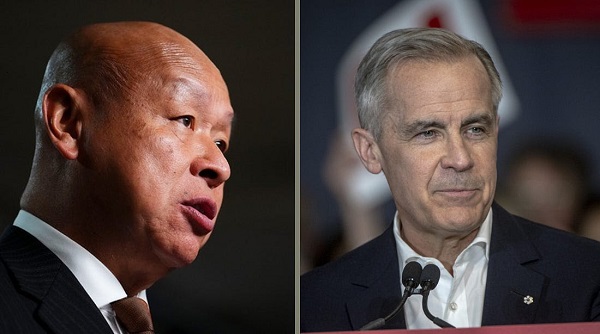

2025 Federal Election17 hours ago2025 Federal Election Interference from China! Carney Pressed to Remove Liberal MP Over CCP Bounty Remark

-

Addictions2 days ago

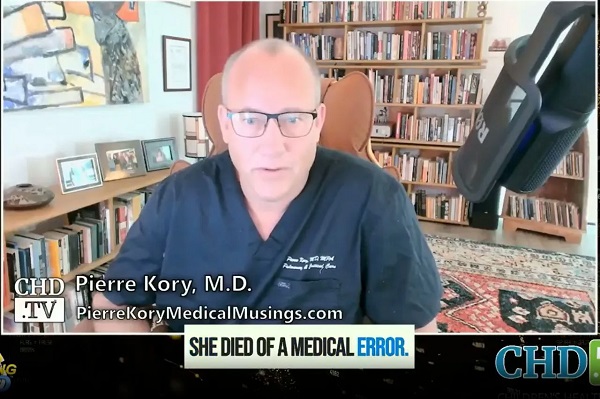

Addictions2 days agoThere’s No Such Thing as a “Safer Supply” of Drugs

-

Uncategorized15 hours ago

Uncategorized15 hours agoPoilievre on 2025 Election Interference – Carney sill hasn’t fired Liberal MP in Chinese election interference scandal

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoCanadian Banks Tied to Chinese Fentanyl Laundering Risk U.S. Treasury Sanctions After Cartel Terror Designation

-

Business2 days ago

Business2 days agoTariff-driven increase of U.S. manufacturing investment would face dearth of workers