Business

How big things could get done—even in Canada

From the Fraser Institute

By Philip Cross

From Newfoundland’s Muskrat Falls hydro project, to Ottawa’s Firearms Registry and the Phoenix pay system, to Montreal’s 1976 Olympics, Canada is a gold medal winner when it comes to wasting tax payer dollars. It doesn’t have to be this way.

Last year, Bent Flyvbjerg, a Danish professor of economic geography specializing in megaprojects, and Canadian journalist Dan Gardner co-authored a book How Big Things Get Done. They investigate what they coin the “Iron Law of Megaprojects,” which holds they routinely come in well over budget, far past projected deadlines, and without the projected benefits.

Unfortunately for taxpayers, the book contains numerous examples of Canadian megaprojects that follow this Law of Megaprojects. The federal government’s infamous firearms registry is a textbook template for how IT projects can go terribly wrong, ending up 590 per cent over budget. The Muskrat Falls hydro project in Newfoundland is cited as a classic demonstration of what happens when hiring a firm with little direct experience managing such a large complex project. Most famously, the 1976 Montreal Olympic Games wins the title for the largest cost overrun in Olympic history, finishing 720 per cent over budget. The authors suggest Montreal’s “Big Owe” stadium “should be considered the unofficial mascot of the modern Olympic Games.”

One thing all these Canadian examples have in common is extensive government involvement. Not that governments learned from their past mistakes. The federal government’s Phoenix pay system fiasco demonstrates that IT remains a black hole, with the government recently announcing it would abandon Phoenix after spending $3.5 billion trying to implement it. Several light train projects across the country have gone off the rails, the poster boy being the system in Ottawa, which is years behind schedule and already $2.5 billion over budget.

There are several reasons why government projects are chronically prone to failure. One is that politicians, especially late in their careers, want legacies in the form of monumental tangible projects irrespective of whether they effectively meet a public need. You can see this dynamic clearly at work today in Canada, as the Trudeau government pushes for a prohibitively expensive (probably more than $100 billion) high-speed rail connection between Windsor and Quebec City. Meanwhile, Ontario Premier Doug Ford promotes a traffic tunnel underneath Highway 401 between Brampton and Scarborough, and Quebec Premier Francois Legault revives plans for a third link connecting Quebec City to the south shore of the St. Lawrence River. While Canada clearly needs more transportation infrastructure, these projects are not the most cost-effective way of meeting the needs of commuters.

Governments deceptively deploy several tricks to help get uneconomic projects built. They routinely produce unrealistically low-cost estimates to make wasteful ego-driven projects appear affordable. Another tried and true tactic is to just “start digging a hole and make it so big, there’s no alternative to coming up with the money to fill it in,” as former San Francisco mayor Willie Brown admitted. This approach preys on the mistaken belief that large sunk costs mean scrapping a project “would be interpreted by the public as ‘throwing away’ the billions of dollars already spent” when it is actually a textbook example of throwing good money after bad.

Unlike other studies of how major infrastructure projects typically are over budget, Flyvbjerg and Gardner have some concrete recommendations on how to manage large projects that respect deadlines and budgets.

These steps include careful consideration of the actual goals of the project (airlines can meet the need for fast transport in the Windsor-Quebec corridor without the expense of high-speed rail), detailed planning and preparation followed by swift execution to minimize costly surprises (summarized by their advice to “think slow, act fast”), accounting for the cost of similar projects in the past, and breaking large projects into smaller modules to allow projects to scale back when they run into trouble. A good example of these principles at work in Canada were several oilsands projects built before 2015, when severe shortages were addressed by firms using modularity and synchronizing their work schedules to free up scarce labour and materials.

However, one major flaw in Flyvbjerg and Gardner’s analysis is their failure to understand the economics of renewable energy. They cite solar and wind projects as examples of projects that routinely finish under budget, a major factor in their declining cost. But building renewable energy is not their only cost to the energy grid, as back-up plants must be maintained for those periods when the sun is not shining or the wind is not blowing, as noted in a recent article by Bjorn Lomborg. The expense of maintaining plants that often are idle raises overall costs. This is why jurisdictions that rely extensively on renewable energy, such as Germany and California, have high energy costs that must be paid either by customers or taxpayers.

However, apart from this mistake, there is much governments and taxpayers can learn from How Big Things Get Done.

Author:

Business

Cuba has lost 24% of it’s population to emigration in the last 4 years

MxM News

MxM News

Quick Hit:

A new study finds Cuba has lost nearly a quarter of its population since 2020, driven by economic collapse and a mass emigration wave unseen outside of war zones. The country’s population now stands at just over 8 million, down from nearly 10 million.

Key Details:

- Independent study estimates Cuba’s population at 8.02 million—down 24% in four years.

- Over 545,000 Cubans left the island in 2024 alone—double the official government figure.

- Demographer warns the crisis mirrors depopulation seen only in wartime, calling it a “systemic collapse.”

Diving Deeper:

Cuba is undergoing a staggering demographic collapse, losing nearly one in four residents over the past four years, according to a new study by economist and demographer Juan Carlos Albizu-Campos. The report estimates that by the end of 2024, Cuba’s population will stand at just over 8 million people—down from nearly 10 million—a 24% drop that Albizu-Campos says is comparable only to what is seen in war-torn nations.

The study, accessed by the Spanish news agency EFE, points to mass emigration as the primary driver. In 2024 alone, 545,011 Cubans are believed to have left the island. That number is more than double what the regime officially acknowledges, as Cuba’s government only counts those heading to the United States, ignoring large flows to destinations like Mexico, Spain, Serbia, and Uruguay.

Albizu-Campos describes the trend as “demographic emptying,” driven by what he calls a “quasi-permanent polycrisis” in Cuba—an interwoven web of political repression, economic freefall, and social decay. For years, Cubans have faced food and medicine shortages, blackout-plagued days, fuel scarcity, soaring inflation, and a broken currency system. The result has been not just migration, but a desperate stampede for the exits.

Yet, the regime continues to minimize the damage. Official figures from the National Office of Statistics and Information (ONEI) put Cuba’s population at just over 10 million in 2023. However, even those numbers acknowledge a shrinking population and the lowest birth rate in decades—confirming the crisis, if not its full scale.

Cuba hasn’t held a census since 2012. The last scheduled one in 2022 has been repeatedly delayed, allegedly due to lack of resources. Experts doubt that any new attempt will be transparent or complete.

Albizu-Campos warns that the government’s refusal to confront the reality of the collapse is obstructing any chance at solutions. More than just a demographic issue, the study describes Cuba’s situation as a “systemic crisis.”

“Havana (Cuba, February 2023)” by Bruno Rijsman licensed under CC BY-SA 2.0 DEED.

Business

Tariff-driven increase of U.S. manufacturing investment would face dearth of workers

From the Fraser Institute

Since 2015, the number of American manufacturing jobs has actually risen modestly. However, as a share of total U.S. employment, manufacturing has dropped from 30 per cent in the 1970s to around 8 per cent in 2024.

Donald Trump has long been convinced that the United States must revitalize its manufacturing sector, having—unwisely, in his view—allowed other countries to sell all manner of foreign-produced manufactured goods in the giant American market. As president, he’s moved quickly to shift the U.S. away from its previous embrace of liberal trade and open markets as cornerstones of its approach to international economic policy —wielding tariffs as his key policy instrument. Since taking office barely two months ago, President Trump has implemented a series of tariff hikes aimed at China and foreign producers of steel and aluminum—important categories of traded manufactured goods—and threatened to impose steep tariffs on most U.S. imports from Canada, Mexico and the European Union. In addition, he’s pledged to levy separate tariffs on imports of automobiles, semi-conductors, lumber, and pharmaceuticals, among other manufactured goods.

In the third week of March, the White House issued a flurry of news releases touting the administration’s commitment to “position the U.S. as a global superpower in manufacturing” and listing substantial new investments planned by multinational enterprises involved in manufacturing. Some of these appear to contemplate relocating manufacturing production in other jurisdictions to the U.S., while others promise new “greenfield” investments in a variety of manufacturing industries.

President Trump’s intense focus on manufacturing is shared by a large slice of America’s political class, spanning both of the main political parties. Yet American manufacturing has hardly withered away in the last few decades. The value of U.S. manufacturing “output” has continued to climb, reaching almost $3 trillion last year (equal to 10 per cent of total GDP). The U.S. still accounts for 15 per cent of global manufacturing production, measured in value-added terms. In fact, among the 10 largest manufacturing countries, it ranks second in manufacturing value-added on a per-capita basis. True, China has become the world’s biggest manufacturing country, representing about 30 per cent of global output. And the heavy reliance of Western economies on China in some segments of manufacturing does give rise to legitimate national security concerns. But the bulk of international trade in manufactured products does not involve goods or technologies that are particularly critical to national security, even if President Trump claims otherwise. Moreover, in the case of the U.S., a majority of two-way trade in manufacturing still takes place with other advanced Western economies (and Mexico).

In the U.S. political arena, much of the debate over manufacturing centres on jobs. And there’s no doubt that employment in the sector has fallen markedly over time, particularly from the early 1990s to the mid-2010s (see table below). Since 2015, the number of American manufacturing jobs has actually risen modestly. However, as a share of total U.S. employment, manufacturing has dropped from 30 per cent in the 1970s to around 8 per cent in 2024.

| U.S. Manufacturing Employment, Select Years (000)* | |

|---|---|

| 1990 | 17,395 |

| 2005 | 14,189 |

| 2010 | 14,444 |

| 2015 | 12,333 |

| 2022 | 12,889 |

| 2024 | 12,760 |

| *December for each year shown. Source: U.S. Bureau of Labor Statistics | |

Economists who have studied the trend conclude that the main factors behind the decline of manufacturing employment include continuous automation, significant gains in productivity across much of the sector, and shifts in aggregate demand and consumption away from goods and toward services. Trade policy has also played a part, notably China’s entry into the World Trade Organization (WTO) in 2001 and the subsequent dramatic expansion of its role in global manufacturing supply chains.

Contrary to what President Trump suggests, manufacturing’s shrinking place in the overall economy is not a uniquely American phenomenon. As Harvard economist Robert Lawrence recently observed “the employment share of manufacturing is declining in mature economies regardless of their overall industrial policy approaches. The trend is apparent both in economies that have adopted free-market policies… and in those with interventionist policies… All of the evidence points to deep and powerful forces that drive the long-term decline in manufacturing’s share of jobs and GDP as countries become richer.”

This brings us back to the president’s seeming determination to rapidly ramp up manufacturing investment and production as a core element of his “America First” program. An important issue overlooked by the administration is where to find the workers to staff a resurgent U.S. manufacturing sector. For while manufacturing has become a notably “capital-intensive” part of the U.S. economy, workers are still needed. And today, it’s hard to see where they will be found. This is especially true given the Trump administration’s well-advertised skepticism about the benefits of immigration.

According to the U.S. Bureau of Labor Statistics, the current unemployment rate across America’s manufacturing industries collectively stands at a record low 2.9 per cent, well below the economy-wide rate of 4.5 per cent. In a recent survey by the National Association of Manufacturers, almost 70 per cent of American manufacturers cited the inability to attract and retain qualified employees as the number one barrier to business growth. A cursory look at the leading industry trade journals confirms that skill and talent shortages remain persistent in many parts of U.S. manufacturing—and that shortages are destined to get worse amid the expected significant jump in manufacturing investment being sought by the Trump administration.

As often seems to be the case with Trump’s stated policy objectives, the math surrounding his manufacturing agenda doesn’t add up. Manufacturing in America is in far better shape than the president acknowledges. And a tariff-driven avalanche of manufacturing investment—should one occur—will soon find the sector reeling from an unprecedented human resource crisis.

Jock Finlayson

Senior Fellow, Fraser Institut

-

Addictions2 days ago

Addictions2 days agoThere’s No Such Thing as a “Safer Supply” of Drugs

-

Uncategorized14 hours ago

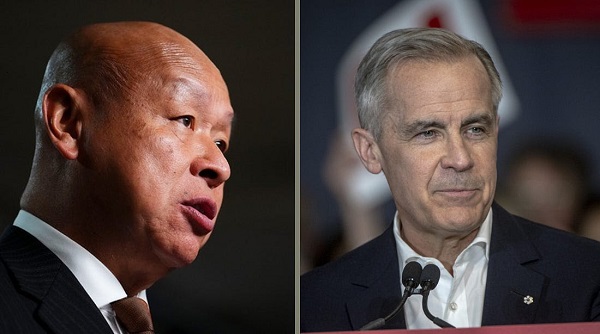

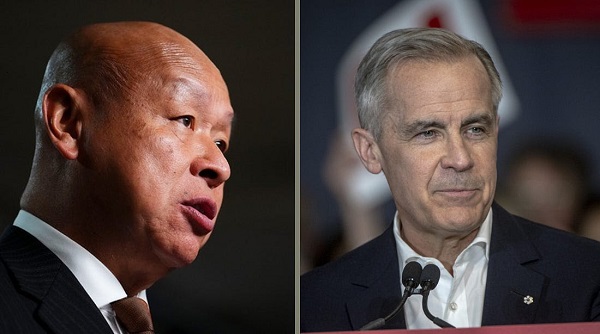

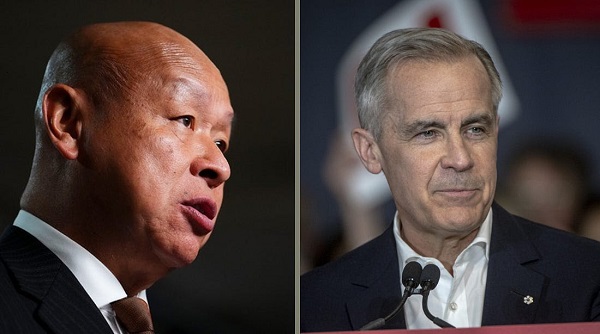

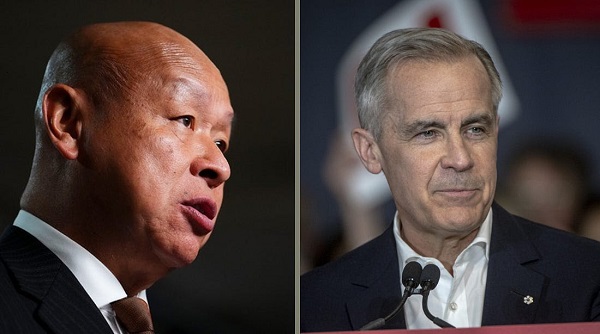

Uncategorized14 hours agoPoilievre on 2025 Election Interference – Carney sill hasn’t fired Liberal MP in Chinese election interference scandal

-

Censorship Industrial Complex11 hours ago

Censorship Industrial Complex11 hours agoWelcome to Britain, Where Critical WhatsApp Messages Are a Police Matter

-

Economy2 days ago

Economy2 days agoClearing the Path: Why Canada Needs Energy Corridors to Compete

-

2025 Federal Election15 hours ago

2025 Federal Election15 hours ago2025 Federal Election Interference from China! Carney Pressed to Remove Liberal MP Over CCP Bounty Remark

-

2025 Federal Election15 hours ago

2025 Federal Election15 hours ago2025 Election Interference – CCP Bounty on Conservative Candidate – Carney Says Nothing

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoCanadian Banks Tied to Chinese Fentanyl Laundering Risk U.S. Treasury Sanctions After Cartel Terror Designation

-

Business2 days ago

Business2 days agoTariff-driven increase of U.S. manufacturing investment would face dearth of workers