Automotive

Electric vehicle weight poses threat to current road infrastructure, safety experts warn

Tesla Model Y

From LifeSiteNews

By Bob Unruh

A report in the Washington Times explains that electric vehicles (EVs) can weigh up to 50 percent more than internal combustion motor vehicles. That extra weight could more easily damage roads, bridges, and parking garages.

If all of the existing headaches for those pushing expensive electric vehicles on resisting American consumers could vanish, there’s still a big one that may have no ready solution.

Already, it appears the U.S. could end up dependent on unfriendly nations for materials for all those batteries. Then there’s the fact that the nation’s grid simply can’t support all that recharging – California already has been sending out advisories for owners not to charge. And then there’s the limited range, extended recharging times, both worsened by bad weather.

But now a report in the Washington Times explains that those batteries are heavy, and EVs can weigh up to 50 percent more than internal combustion motor vehicles.

And that weight damages roads, bridges and parking garages, with those vehicles easily plowing through safety guardrails while posing a higher danger to other drivers, pedestrians and bicyclists traveling the same routes.

“The problems associated with EVs are poised to grow as more consumers purchase the cars under the Biden administration’s plan to eliminate gas-powered vehicles and the tailpipe emissions that come with them,” the report explained.

It explained engineers writing recently for Structure Magazine suggested construction companies, and building codes, need to make accommodation for the higher weight.

Parking garages, they said, should be redesigned to hold more weight.

That’s because some hold hundreds of vehicles, and just one EV. A Ford truck, weighs in at 8,240 pounds, nearly a ton (about 1,000 kg) more than the gas-powered version of the same pickup.

“Significantly increasing passenger vehicle weights combined with recently reduced structural design requirements will result in reduced factors of safety and increased maintenance and repair costs for parking structures,” the engineers wrote. “There are many cases of parking structure failures, and the growing demand for EVs will only increase the probability of failure.”

Then there are those guardrails, installed to minimize damage when traffic goes awry.

They are installed between lanes for traffic moving opposite directions, between lanes and edge drop-offs and more.

That concern comes out of a procedure at a test facility in Nebraska, where examiners took a 3.6-ton Rivian R1 and sent it into a metal guardrail at 62 mph, first head-on, then at an angle.

Both times it “ripped through” the guardrail and continued into what would have been lanes for oncoming traffic, the report revealed.

The conclusion was simple: making vehicles much heavier means “a lot more force” is required to redirect the vehicle.

University of Nebraska professor Cody Stolle, told the Times, “We found these guardrail systems don’t have great compatibility with these [electric] vehicles yet.”

The heavier vehicles also could cause more damage to other vehicles in collisions.

The report said an insurance institute expert confirmed the weight provides more protection to those inside the EV, but at the expense of anyone in another vehicle involved in an accident.

Joe Biden has insisted over and over that consumers should be buying the much more expensive and often less reliable electric cars the government programs subsidize.

The weight differences are significant. The report said the Tesla Model Y is more than 4,400 pounds while the similar size gas-powered Honda Accord is 3,300. Kia makes multiple SUVs, with the gas model weighting 3,900 pounds and the EV unit nearly 6,500.

Residential roads already are not engineered to handle the heavy weight on highways, and the lifespan of bridges could be reduced with much heavier traffic, the report said.

Sen. Marco Rubio, R-Fla., recently said, “EVs are typically much heavier compared to similarly sized, gas-powered vehicles, which will put additional strain on America’s transportation infrastructure. The American Society of Civil Engineers warns that an increase in EVs could substantially reduce the lifespan of roads and bridges, necessitating further investment in infrastructure.”

Reprinted with permission from the WND News Center.

Automotive

Ford’s EV Fiasco Fallout Hits Hard

From the Daily Caller News Foundation

I’ve written frequently here in recent years about the financial fiasco that has hit Ford Motor Company and other big U.S. carmakers who made the fateful decision to go in whole hog in 2021 to feed at the federal subsidy trough wrought on the U.S. economy by the Joe Biden autopen presidency. It was crony capitalism writ large, federal rent seeking on the grandest scale in U.S. history, and only now are the chickens coming home to roost.

Ford announced on Monday that it will be forced to take $19.5 billion in special charges as its management team embarks on a corporate reorganization in a desperate attempt to unwind the financial carnage caused by its failed strategies and investments in the electric vehicles space since 2022.

Cancelled is the Ford F-150 Lightning, the full-size electric pickup that few could afford and fewer wanted to buy, along with planned introductions of a second pricey pickup and fully electric vans and commercial vehicles. Ford will apparently keep making its costly Mustang Mach-E EV while adjusting the car’s features and price to try to make it more competitive. There will be a shift to making more hybrid models and introducing new lines of cheaper EVs and what the company calls “extended range electric vehicles,” or EREVs, which attach a gas-fueled generator to recharge the EV batteries while the car is being driven.

Dear Readers:

As a nonprofit, we are dependent on the generosity of our readers.

Please consider making a small donation of any amount here.

Thank you!

“The $50k, $60k, $70k EVs just weren’t selling; We’re following customers to where the market is,” Farley said. “We’re going to build up our whole lineup of hybrids. It’s gonna be better for the company’s profitability, shareholders and a lot of new American jobs. These really expensive $70k electric trucks, as much as I love the product, they didn’t make sense. But an EREV that goes 700 miles on a tank of gas, for 90% of the time is all-electric, that EREV is a better solution for a Lightning than the current all-electric Lightning.”

It all makes sense to Mr. Farley, but one wonders how much longer the company’s investors will tolerate his presence atop the corporate management pyramid if the company’s financial fortunes don’t turn around fast.

To Ford’s and Farley’s credit, the company has, unlike some of its competitors (GM, for example), been quite transparent in publicly revealing the massive losses it has accumulated in its EV projects since 2022. The company has reported its EV enterprise as a separate business unit called Model-E on its financial filings, enabling everyone to witness its somewhat amazing escalating EV-related losses since 2022:

• 2022 – Net loss of $2.2 billion

• 2023 – Net loss of $4.7 billion

• 2024 – Net loss of $5.1 billion

Add in the company’s $3.6 billion in losses recorded across the first three quarters of 2025, and you arrive at a total of $15.6 billion net losses on EV-related projects and processes in less than four calendar years. Add to that the financial carnage detailed in Monday’s announcement and the damage from the company’s financial electric boogaloo escalates to well above $30 billion with Q4 2025’s damage still to be added to the total.

Ford and Farley have benefited from the fact that the company’s lineup of gas-and-diesel powered cars have remained strongly profitable, resulting in overall corporate profits each year despite the huge EV-related losses. It is also fair to point out that all car companies were under heavy pressure from the Biden government to either produce battery electric vehicles or be penalized by onerous federal regulations.

Now, with the Trump administration rescinding Biden’s harsh mandates and canceling the absurdly unattainable fleet mileage requirements, Ford and other companies will be free to make cars Americans actually want to buy. Better late than never, as they say, but the financial fallout from it all is likely just beginning to be made public.

- David Blackmon is an energy writer and consultant based in Texas. He spent 40 years in the oil and gas business, where he specialized in public policy and communications.

Automotive

Politicians should be honest about environmental pros and cons of electric vehicles

From the Fraser Institute

By Annika Segelhorst and Elmira Aliakbari

According to Steven Guilbeault, former environment minister under Justin Trudeau and former member of Prime Minister Carney’s cabinet, “Switching to an electric vehicle is one of the most impactful things Canadians can do to help fight climate change.”

And the Carney government has only paused Trudeau’s electric vehicle (EV) sales mandate to conduct a “review” of the policy, despite industry pressure to scrap the policy altogether.

So clearly, according to policymakers in Ottawa, EVs are essentially “zero emission” and thus good for environment.

But is that true?

Clearly, EVs have some environmental advantages over traditional gasoline-powered vehicles. Unlike cars with engines that directly burn fossil fuels, EVs do not produce tailpipe emissions of pollutants such as nitrogen dioxide and carbon monoxide, and do not release greenhouse gases (GHGs) such as carbon dioxide. These benefits are real. But when you consider the entire lifecycle of an EV, the picture becomes much more complicated.

Unlike traditional gasoline-powered vehicles, battery-powered EVs and plug-in hybrids generate most of their GHG emissions before the vehicles roll off the assembly line. Compared with conventional gas-powered cars, EVs typically require more fossil fuel energy to manufacture, largely because to produce EVs batteries, producers require a variety of mined materials including cobalt, graphite, lithium, manganese and nickel, which all take lots of energy to extract and process. Once these raw materials are mined, processed and transported across often vast distances to manufacturing sites, they must be assembled into battery packs. Consequently, the manufacturing process of an EV—from the initial mining of materials to final assembly—produces twice the quantity of GHGs (on average) as the manufacturing process for a comparable gas-powered car.

Once an EV is on the road, its carbon footprint depends on how the electricity used to charge its battery is generated. According to a report from the Canada Energy Regulator (the federal agency responsible for overseeing oil, gas and electric utilities), in British Columbia, Manitoba, Quebec and Ontario, electricity is largely produced from low- or even zero-carbon sources such as hydro, so EVs in these provinces have a low level of “indirect” emissions.

However, in other provinces—particularly Alberta, Saskatchewan and Nova Scotia—electricity generation is more heavily reliant on fossil fuels such as coal and natural gas, so EVs produce much higher indirect emissions. And according to research from the University of Toronto, in coal-dependent U.S. states such as West Virginia, an EV can emit about 6 per cent more GHG emissions over its entire lifetime—from initial mining, manufacturing and charging to eventual disposal—than a gas-powered vehicle of the same size. This means that in regions with especially coal-dependent energy grids, EVs could impose more climate costs than benefits. Put simply, for an EV to help meaningfully reduce emissions while on the road, its electricity must come from low-carbon electricity sources—something that does not happen in certain areas of Canada and the United States.

Finally, even after an EV is off the road, it continues to produce emissions, mainly because of the battery. EV batteries contain components that are energy-intensive to extract but also notoriously challenging to recycle. While EV battery recycling technologies are still emerging, approximately 5 per cent of lithium-ion batteries, which are commonly used in EVs, are actually recycled worldwide. This means that most new EVs feature batteries with no recycled components—further weakening the environmental benefit of EVs.

So what’s the final analysis? The technology continues to evolve and therefore the calculations will continue to change. But right now, while electric vehicles clearly help reduce tailpipe emissions, they’re not necessarily “zero emission” vehicles. And after you consider the full lifecycle—manufacturing, charging, scrapping—a more accurate picture of their environmental impact comes into view.

-

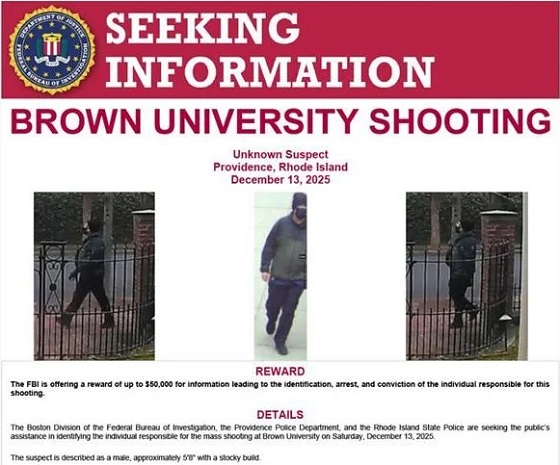

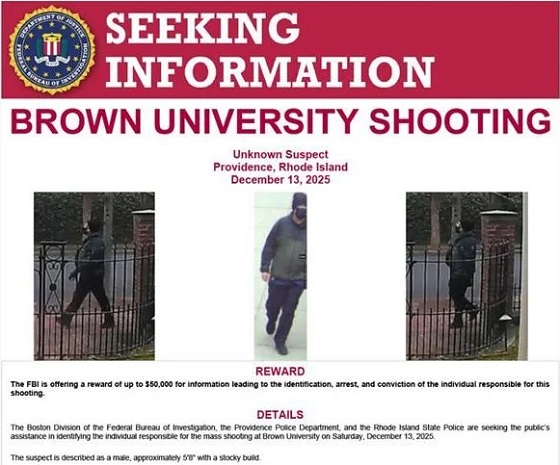

Crime2 days ago

Crime2 days agoBrown University shooter dead of apparent self-inflicted gunshot wound

-

Health1 day ago

Health1 day agoRFK Jr reversing Biden-era policies on gender transition care for minors

-

Alberta1 day ago

Alberta1 day agoAlberta’s new diagnostic policy appears to meet standard for Canada Health Act compliance

-

Censorship Industrial Complex1 day ago

Censorship Industrial Complex1 day agoCanadian university censors free speech advocate who spoke out against Indigenous ‘mass grave’ hoax

-

Business19 hours ago

Business19 hours agoArgentina’s Milei delivers results free-market critics said wouldn’t work

-

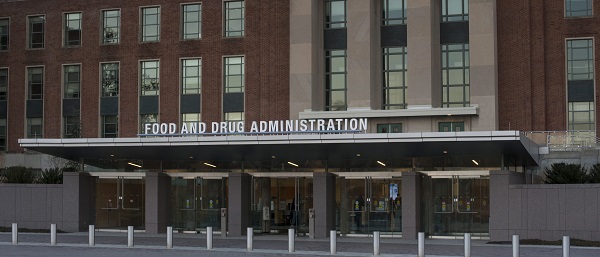

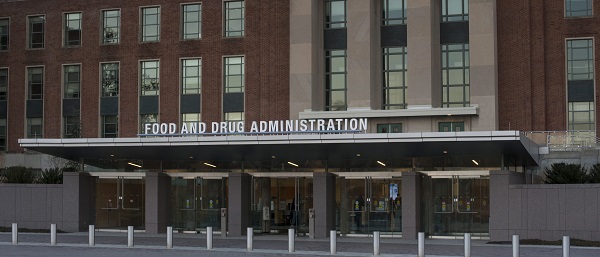

Daily Caller1 day ago

Daily Caller1 day agoEx-FDA Commissioners Against Higher Vaccine Standards Took $6 Million From COVID Vaccine Makers

-

Business2 days ago

Business2 days agoTrump signs order reclassifying marijuana as Schedule III drug

-

COVID-191 day ago

COVID-191 day agoFreedom Convoy protester appeals after judge dismissed challenge to frozen bank accounts