Automotive

Can Metal Mining Match the Speed of the Planned Electric Vehicle Transition?

From the Fraser Institute

The governments of Canada, the United States, and many other nations are mandating a shift in vehicle technology: away from vehicles powered primarily by internal combustion engines, and toward vehicles powered primarily with electricity stored on board in batteries.

Canada’s government has established policies designed to push automakers to achieve the government’s goal of having 35 percent of all new medium- and heavy-duty vehicle sales be electric by 2030, rising to 100 percent of all new medium- and heavy-duty vehicle sales being electric by 2040.

The US has set a target requiring 50 percent of all new passenger cars and light trucks sold in 2030 be electric, or largely electric hybrid vehicles. These timelines are ambitious, calling for a major expansion of the prevalence of electric vehicles (EVs) in the major vehicle classes in a very short time—only 7 to 10 years.

Barring breakthrough developments in battery technology, this massive and rapid expansion of battery-electric vehicle production will require a correspondingly massive and rapid expansion of the mining and refining of the metals and rare earth elements critical to battery-electric vehicle technology.

The International Energy Agency (IEA) suggests that to meet international EV adoption pledges, the world will need 50 new lithium mines by 2030, along with 60 new nickel mines, and 17 new cobalt mines. The materials needed for cathode production will require 50 more new mines, and anode materials another 40. The battery cells will require 90 new mines, and EVs themselves another 81. In total, this adds up to 388 new mines. For context, as of 2021, there were only 270 metal mines operating across the US, and only 70 in Canada. If Canada and the US wish to have internal supply chains for these vital EV metals, they have a lot of mines to establish in a very short period.

Historically, however, mining and refining facilities are both slow to develop and are highly uncertain endeavors plagued by regulatory uncertainty and by environmental and regulatory barriers. Lithium production timelines, for example, are approximately 6 to 9 years, while production timelines (from application to production) for nickel are approximately 13 to 18 years, according to the IEA.

The establishment of aggressive and short-term EV adoption goals sets up a potential conflict with metal and mineral production, which is historically characterized by long lead-times and long production timelines. The risk that mineral and mining production will fall short of projected demand is significant, and could greatly affect the success of various governments’ plans for EV transition.

Author:

Automotive

Canadians’ Interest in Buying an EV Falls for Third Year in a Row

From Energy Now

Electric vehicle prices fell 7.8 per cent in the last quarter of 2024 year-over-year, according to the AutoTader price index

Fewer Canadians are considering buying an electric vehicle, marking the third year in a row interest has dropped despite lower EV prices, a survey from AutoTrader shows.

Forty-two per cent of survey respondents say they’re considering an EV as their next vehicle, down from 46 per cent last year. In 2022, 68 per cent said they would consider buying an EV.

Meanwhile, 29 per cent of respondents say they would exclusively consider buying an EV — a significant drop from 40 per cent last year.

The report, which surveyed 1,801 people on the AutoTrader website, shows drivers are concerned about reduced government incentives, a lack of infrastructure and long-term costs despite falling prices.

Electric vehicle prices fell 7.8 per cent in the last quarter of 2024 year-over-year, according to the AutoTader price index.

The survey, conducted between Feb. 13 and March 12, shows 68 per cent of non-EV owners say government incentives could influence their decision, while a little over half say incentives increase their confidence in buying an EV.

Automotive

Hyundai moves SUV production to U.S.

MxM News

MxM News

Quick Hit:

Hyundai is responding swiftly to 47th President Donald Trump’s newly implemented auto tariffs by shifting key vehicle production from Mexico to the U.S. The automaker, heavily reliant on the American market, has formed a specialized task force and committed billions to American manufacturing, highlighting how Trump’s America First economic policies are already impacting global business decisions.

Key Details:

-

Hyundai has created a tariffs task force and is relocating Tucson SUV production from Mexico to Alabama.

-

Despite a 25% tariff on car imports that began April 3, Hyundai reported a 2% gain in Q1 operating profit and maintained earnings guidance.

-

Hyundai and Kia derive one-third of their global sales from the U.S., where two-thirds of their vehicles are imported.

Diving Deeper:

In a direct response to President Trump’s decisive new tariffs on imported automobiles, Hyundai announced Thursday it has mobilized a specialized task force to mitigate the financial impact of the new trade policy and confirmed production shifts of one of its top-selling models to the United States. The move underscores the gravity of the new 25% import tax and the economic leverage wielded by a White House that is now unambiguously prioritizing American industry.

Starting with its popular Tucson SUV, Hyundai is transitioning some manufacturing from Mexico to its Alabama facility. Additional consideration is being given to relocating production away from Seoul for other U.S.-bound vehicles, signaling that the company is bracing for the long-term implications of Trump’s tariffs.

This move comes as the 25% import tax on vehicles went into effect April 3, with a matching tariff on auto parts scheduled to hit May 3. Hyundai, which generates a full third of its global revenue from American consumers, knows it can’t afford to delay action. Notably, U.S. retail sales for Hyundai jumped 11% last quarter, as car buyers rushed to purchase vehicles before prices inevitably climb due to the tariff.

Despite the trade policy, Hyundai reported a 2% uptick in first-quarter operating profit and reaffirmed its earnings projections, indicating confidence in its ability to adapt. Yet the company isn’t taking chances. Ahead of the tariffs, Hyundai stockpiled over three months of inventory in U.S. markets, hoping to blunt the initial shock of the increased import costs.

In a significant show of good faith and commitment to U.S. manufacturing, Hyundai last month pledged a massive $21 billion investment into its new Georgia plant. That announcement was made during a visit to the White House, just days before President Trump unveiled the auto tariff policy — a strategic alignment with a pro-growth, pro-America agenda.

Still, the challenges are substantial. The global auto industry depends on complex, multi-country supply chains, and analysts warn that tariffs will force production costs higher. Hyundai is holding the line on pricing for now, promising to keep current model prices stable through June 2. After that, however, price adjustments are on the table, potentially passing the burden to consumers.

South Korea, which remains one of the largest exporters of automobiles to the U.S., is not standing idle. A South Korean delegation is scheduled to meet with U.S. trade officials in Washington Thursday, marking the start of negotiations that could redefine the two nations’ trade dynamics.

President Trump’s actions represent a sharp pivot from the era of global corporatism that defined trade under the Obama-Biden administration. Hyundai’s swift response proves that when the U.S. government puts its market power to work, foreign companies will move mountains — or at least entire assembly lines — to stay in the game.

-

Alberta2 days ago

Alberta2 days agoGovernments in Alberta should spur homebuilding amid population explosion

-

International2 days ago

International2 days agoHistory in the making? Trump, Zelensky hold meeting about Ukraine war in Vatican ahead of Francis’ funeral

-

Alberta2 days ago

Alberta2 days agoLow oil prices could have big consequences for Alberta’s finances

-

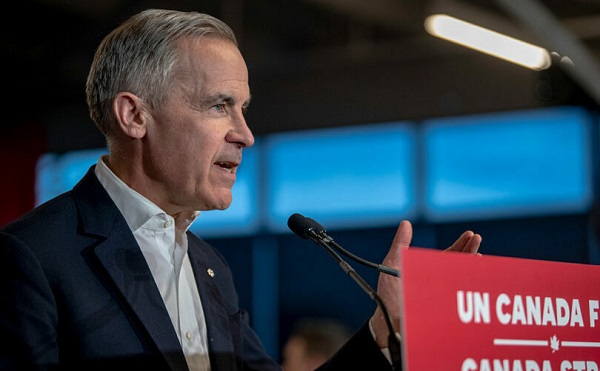

2025 Federal Election2 days ago

2025 Federal Election2 days agoCarney’s budget is worse than Trudeau’s

-

Business2 days ago

Business2 days agoIt Took Trump To Get Canada Serious About Free Trade With Itself

-

C2C Journal2 days ago

C2C Journal2 days ago“Freedom of Expression Should Win Every Time”: In Conversation with Freedom Convoy Trial Lawyer Lawrence Greenspon

-

2025 Federal Election21 hours ago

2025 Federal Election21 hours agoColumnist warns Carney Liberals will consider a home equity tax on primary residences

-

2025 Federal Election20 hours ago

2025 Federal Election20 hours agoNine Dead After SUV Plows Into Vancouver Festival Crowd, Raising Election-Eve Concerns Over Public Safety