Automotive

The EV ‘Bloodbath’ Arrives Early

From the Daily Caller News Foundation

From the Daily Caller News Foundation

By David Blackmon

Ever since March 16, when presidential candidate Donald Trump created a controversy by predicting President Joe Biden’s efforts to force Americans to convert their lives to electric-vehicle (EV) lifestyles would end in a “bloodbath” for the U.S. auto industry, the industry’s own disastrous results have consistently proven him accurate.

The latest example came this week when Ford Motor Company reported that it had somehow managed to lose $132,000 per unit sold during Q1 2024 in its Model e EV division. The disastrous first quarter results follow the equally disastrous results for 2023, when the company said it lost $4.7 billion in Model e for the full 12-month period.

While the company has remained profitable overall thanks to strong demand for its legacy internal combustion SUV, pickup, and heavy vehicle models, the string of major losses in its EV line led the company to announce a shift in strategic vision in early April. Ford CEO Jim Farley said then that the company would delay the introduction of additional planned all-electric models and scale back production of current models like the F-150 Lightning pickup while refocusing efforts on introducing new hybrid models across its business line.

General Motors reported it had good overall Q1 results, but they were based on strong sales of its gas-powered SUV and truck models, not its EVs. GM is so gun-shy about reporting EV-specific results that it doesn’t break them out in its quarterly reports, so there is no way of knowing what the real bottom line amounts to from that part of the business. This is possibly a practice Ford should consider adopting.

After reporting its own disappointing Q1 results in which adjusted earnings collapsed by 48% and deliveries dropped by 20% from the previous quarter, Tesla announced it is laying off 10 percent of its global workforce, including 2,688 employees at its Austin plant, where its vaunted Cybertruck is manufactured. Since its introduction in November, the Cybertruck has been beset by buyer complaints ranging from breakdowns within minutes after taking delivery, to its $3,000 camping tent feature failing to deploy, to an incident in which one buyer complained his vehicle shut down for 5 hours after he failed to put the truck in “carwash mode” before running it through a local car wash.

Meanwhile, international auto rental company Hertz is now fire selling its own fleet of Teslas and other EV models in its efforts to salvage a little final value from what is turning out to be a disastrous EV gamble. In a giant fit of green virtue-signaling, the company invested whole hog into the Biden subsidy program in 2021 with a mass purchase of as many as 100,000 Teslas and 50,000 Polestar models, only to find that customer demand for renting electric cars was as tepid as demand to buy them outright. For its troubles, Hertz reported it had lost $392 million during Q1, attributing $195 million of the loss to its EV struggles. Hertz’s share price plummeted by about 20% on April 25, and was down by 55% for the year.

If all this financial carnage does not yet constitute a “bloodbath” for the U.S. EV sector, it is difficult to imagine what would. But wait: It really isn’t all that hard to imagine at all, is it? When he used that term back in March, Trump was referring not just to the ruinous Biden subsidy program, but also to plans by China to establish an EV-manufacturing beachhead in Mexico, from which it would be able to flood the U.S. market with its cheap but high-quality electric models. That would definitely cause an already disastrous domestic EV market to get even worse, wouldn’t it?

The bottom line here is that it is becoming obvious even to ardent EV fans that US consumer demand for EVs has reached a peak long before the industry and government expected it would.

It’s a bit of a perfect storm, one that rent-seeking company executives and obliging policymakers brought upon themselves. Given that this outcome was highly predictable, with so many warning that it was in fact inevitable, a reckoning from investors and corporate boards and voters will soon come due. It could become a bloodbath of its own, and perhaps it should.

David Blackmon is an energy writer and consultant based in Texas. He spent 40 years in the oil and gas business, where he specialized in public policy and communications.

Automotive

Canadians’ Interest in Buying an EV Falls for Third Year in a Row

From Energy Now

Electric vehicle prices fell 7.8 per cent in the last quarter of 2024 year-over-year, according to the AutoTader price index

Fewer Canadians are considering buying an electric vehicle, marking the third year in a row interest has dropped despite lower EV prices, a survey from AutoTrader shows.

Forty-two per cent of survey respondents say they’re considering an EV as their next vehicle, down from 46 per cent last year. In 2022, 68 per cent said they would consider buying an EV.

Meanwhile, 29 per cent of respondents say they would exclusively consider buying an EV — a significant drop from 40 per cent last year.

The report, which surveyed 1,801 people on the AutoTrader website, shows drivers are concerned about reduced government incentives, a lack of infrastructure and long-term costs despite falling prices.

Electric vehicle prices fell 7.8 per cent in the last quarter of 2024 year-over-year, according to the AutoTader price index.

The survey, conducted between Feb. 13 and March 12, shows 68 per cent of non-EV owners say government incentives could influence their decision, while a little over half say incentives increase their confidence in buying an EV.

Automotive

Hyundai moves SUV production to U.S.

MxM News

MxM News

Quick Hit:

Hyundai is responding swiftly to 47th President Donald Trump’s newly implemented auto tariffs by shifting key vehicle production from Mexico to the U.S. The automaker, heavily reliant on the American market, has formed a specialized task force and committed billions to American manufacturing, highlighting how Trump’s America First economic policies are already impacting global business decisions.

Key Details:

-

Hyundai has created a tariffs task force and is relocating Tucson SUV production from Mexico to Alabama.

-

Despite a 25% tariff on car imports that began April 3, Hyundai reported a 2% gain in Q1 operating profit and maintained earnings guidance.

-

Hyundai and Kia derive one-third of their global sales from the U.S., where two-thirds of their vehicles are imported.

Diving Deeper:

In a direct response to President Trump’s decisive new tariffs on imported automobiles, Hyundai announced Thursday it has mobilized a specialized task force to mitigate the financial impact of the new trade policy and confirmed production shifts of one of its top-selling models to the United States. The move underscores the gravity of the new 25% import tax and the economic leverage wielded by a White House that is now unambiguously prioritizing American industry.

Starting with its popular Tucson SUV, Hyundai is transitioning some manufacturing from Mexico to its Alabama facility. Additional consideration is being given to relocating production away from Seoul for other U.S.-bound vehicles, signaling that the company is bracing for the long-term implications of Trump’s tariffs.

This move comes as the 25% import tax on vehicles went into effect April 3, with a matching tariff on auto parts scheduled to hit May 3. Hyundai, which generates a full third of its global revenue from American consumers, knows it can’t afford to delay action. Notably, U.S. retail sales for Hyundai jumped 11% last quarter, as car buyers rushed to purchase vehicles before prices inevitably climb due to the tariff.

Despite the trade policy, Hyundai reported a 2% uptick in first-quarter operating profit and reaffirmed its earnings projections, indicating confidence in its ability to adapt. Yet the company isn’t taking chances. Ahead of the tariffs, Hyundai stockpiled over three months of inventory in U.S. markets, hoping to blunt the initial shock of the increased import costs.

In a significant show of good faith and commitment to U.S. manufacturing, Hyundai last month pledged a massive $21 billion investment into its new Georgia plant. That announcement was made during a visit to the White House, just days before President Trump unveiled the auto tariff policy — a strategic alignment with a pro-growth, pro-America agenda.

Still, the challenges are substantial. The global auto industry depends on complex, multi-country supply chains, and analysts warn that tariffs will force production costs higher. Hyundai is holding the line on pricing for now, promising to keep current model prices stable through June 2. After that, however, price adjustments are on the table, potentially passing the burden to consumers.

South Korea, which remains one of the largest exporters of automobiles to the U.S., is not standing idle. A South Korean delegation is scheduled to meet with U.S. trade officials in Washington Thursday, marking the start of negotiations that could redefine the two nations’ trade dynamics.

President Trump’s actions represent a sharp pivot from the era of global corporatism that defined trade under the Obama-Biden administration. Hyundai’s swift response proves that when the U.S. government puts its market power to work, foreign companies will move mountains — or at least entire assembly lines — to stay in the game.

-

Automotive2 days ago

Automotive2 days agoHyundai moves SUV production to U.S.

-

Entertainment2 days ago

Entertainment2 days agoPedro Pascal launches attack on J.K. Rowling over biological sex views

-

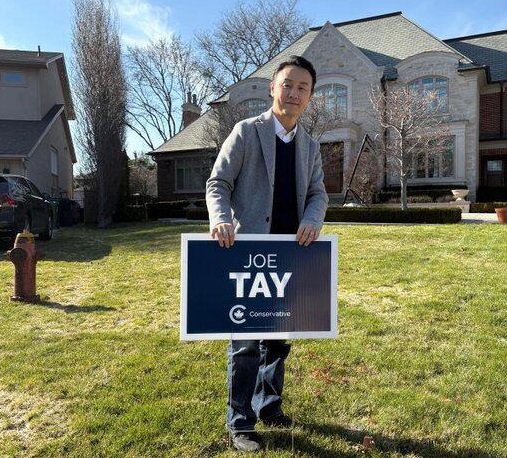

2025 Federal Election1 day ago

2025 Federal Election1 day agoAs PM Poilievre would cancel summer holidays for MP’s so Ottawa can finally get back to work

-

armed forces21 hours ago

armed forces21 hours agoYet another struggling soldier says Veteran Affairs Canada offered him euthanasia

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoPoilievre Campaigning To Build A Canadian Economic Fortress

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoThe Cost of Underselling Canadian Oil and Gas to the USA

-

Automotive2 days ago

Automotive2 days agoCanadians’ Interest in Buying an EV Falls for Third Year in a Row

-

conflict20 hours ago

conflict20 hours agoWhy are the globalists so opposed to Trump’s efforts to make peace in Ukraine?