Alberta

Oil sands technology competition to generate low emissions carbon fibre moves into final phase

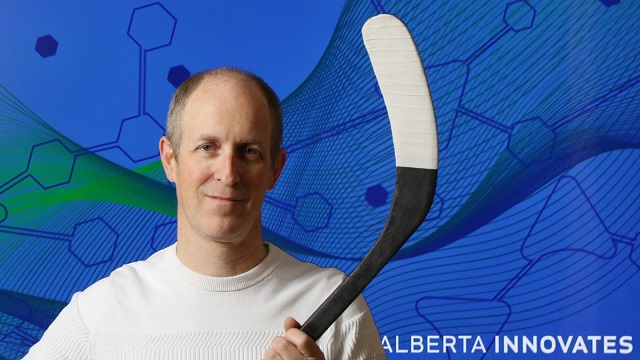

Bryan Helfenbaum, associate vice-president of clean energy with Alberta Innovates, holds a hockey stick made with carbon fibre derived from oil sands bitumen. Photo by Dave Chidley for the Canadian Energy Centre

From the Canadian Energy Centre

By Will Gibson and Deborah Jaremko

Study found carbon fibre made from oil sands bitumen has 69 per cent lower emissions than conventional sources

Having spent most of a long and distinguished academic career working with metals, Weixing Chen became fascinated by the potential of repurposing a heavy hydrocarbon from Alberta’s oil sands into a high-value product for a low-carbon economy.

The product is carbon fibre – thin as human hair but four times stronger than steel – and research has shown producing it from oil sands bitumen generates lower greenhouse gas emissions than today’s sources.

“This is a great opportunity for me to challenge myself moving forward to develop this technology that will benefit society,” says Chen, a chemical and material engineering professor at the University of Alberta.

His team at Edmonton-based Thread Innovations is one of five receiving a total $15 million in funding in the final round of the Carbon Fibre Grand Challenge, announced in December.

Great potential for carbon fibre

With its light weight and high strength, today carbon fibre is used in products like aircraft and spacecraft parts, racing car bodies, bicycles, hockey sticks and golf clubs.

It has great potential, but its use is limited by cost. Carbon fibre averages $10 to $12 per pound, compared to less than $1 per pound for steel.

Part of the Alberta competition is that the carbon fibre derived from oil sands bitumen must cost 50 per cent less than current carbon fibre products.

This would unlock new markets for carbon fibre, says Byran Helfenbaum, associate vice-president of clean energy for Alberta Innovates, which is funding the challenge along with Emissions Reduction Alberta.

“At the end of this phase, the intention is the technology is at a point where a company could make a funding decision for if not a commercial project, then at least a commercial demonstration project,” he says.

“It’s really to get it out of the lab and start hitting the key specifications, identifying the existing and new markets, and pumping out prototypes that can be tested. We have already generated our first two prototypes, a truck side mirror and a hockey stick, but we need to go bigger and faster and test a wide range of market opportunities.”

Long-term need for carbon-based products

The future is likely to be full of carbon fibre products, Helfenbaum says.

“This ‘low-carbon future’ is a misnomer. When we say low-carbon future, what we mean is let’s keep carbon out of the atmosphere. Carbon is still going to be around us in solid form, and probably in increasingly higher amounts,” he says.

“We’re going to have 10 billion people on the planet by mid-century. They need energy, but they also need stuff. They need housing, infrastructure, and consumer goods. And most of that stuff is or can be made of pure carbon.”

Lower emissions from oil sands carbon fibre

Most carbon fibre today is generated from a chemical compound called polyacrylonitrile (PAN), which is derived from a component of natural gas.

A recent study by researchers at the University of Alberta found that life cycle emissions from carbon fibre derived from oil sands bitumen are 69 per cent lower than PAN-based product.

It’s the high carbon content of oil sands bitumen that provides the benefit, Helfenbaum says.

“The heaviest fraction of bitumen takes more energy to break down to be turned into fuels. But that same fraction can be used to produce carbon fibre with fewer greenhouse gas emissions than the current PAN process,” he says.

“If we are successful in reducing its cost, then it can be deployed into new markets that will further reduce carbon emissions, such as lightening passenger vehicles and improving the longevity of concrete infrastructure.”

Adding value while reducing emissions

The Carbon Fibre Grand Challenge is part of Alberta Innovates’ broader Bitumen Beyond Combustion research program. The work considers opportunities to use bitumen to create value-added products other than fuels like gasoline and diesel.

“From an economic perspective, the Bitumen Beyond Combustion program could triple the value of a barrel of bitumen,” Helfenbaum says.

“Carbon fibre is among the most valuable of those products, but it’s not the only one. This is potentially in the tens of billions of dollars a year of gross revenue opportunity, so this is transformational.”

It also presents environmental benefits.

“Eighty per cent of the emissions associated with petroleum happen at combustion of gasoline, diesel, and jet fuel so by diverting into these products, that becomes carbon that is sequestered forever and doesn’t get into the atmosphere,” he says.

Pathway to commercial production

Winners of the grand challenge will have a credible pathway to manufacturing 2,000 tonnes or more of carbon fibre per year. The challenge is scheduled to end in summer 2026.

Thread Innovations is building a new facility to produce samples for potential buyers and demonstrate the ability to scale up production. This phase will also focus on improving characteristics of the carbon fibre produced by their technology to build commercial demand.

“Our target is to complete the current project and then establish a commercialization plan in 2025,” says Chen.

Alberta

The Canadian Energy Centre’s biggest stories of 2025

From the Canadian Energy Centre

Canada’s energy landscape changed significantly in 2025, with mounting U.S. economic pressures reinforcing the central role oil and gas can play in safeguarding the country’s independence.

Here are the Canadian Energy Centre’s top five most-viewed stories of the year.

5. Alberta’s massive oil and gas reserves keep growing – here’s why

The Northern Lights, aurora borealis, make an appearance over pumpjacks near Cremona, Alta., Thursday, Oct. 10, 2024. CP Images photo

Analysis commissioned this spring by the Alberta Energy Regulator increased the province’s natural gas reserves by more than 400 per cent, bumping Canada into the global top 10.

Even with record production, Alberta’s oil reserves – already fourth in the world – also increased by seven billion barrels.

According to McDaniel & Associates, which conducted the report, these reserves are likely to become increasingly important as global demand continues to rise and there is limited production growth from other sources, including the United States.

4. Canada’s pipeline builders ready to get to work

Canada could be on the cusp of a “golden age” for building major energy projects, said Kevin O’Donnell, executive director of the Mississauga, Ont.-based Pipe Line Contractors Association of Canada.

That eagerness is shared by the Edmonton-based Progressive Contractors Association of Canada (PCA), which launched a “Let’s Get Building” advocacy campaign urging all Canadian politicians to focus on getting major projects built.

“The sooner these nation-building projects get underway, the sooner Canadians reap the rewards through new trading partnerships, good jobs and a more stable economy,” said PCA chief executive Paul de Jong.

3. New Canadian oil and gas pipelines a $38 billion missed opportunity, says Montreal Economic Institute

Steel pipe in storage for the Trans Mountain Pipeline expansion in 2022. Photo courtesy Trans Mountain Corporation

In March, a report by the Montreal Economic Institute (MEI) underscored the economic opportunity of Canada building new pipeline export capacity.

MEI found that if the proposed Energy East and Gazoduq/GNL Quebec projects had been built, Canada would have been able to export $38 billion worth of oil and gas to non-U.S. destinations in 2024.

“We would be able to have more prosperity for Canada, more revenue for governments because they collect royalties that go to government programs,” said MEI senior policy analyst Gabriel Giguère.

“I believe everybody’s winning with these kinds of infrastructure projects.”

2. Keyera ‘Canadianizes’ natural gas liquids with $5.15 billion acquisition

Keyera Corp.’s natural gas liquids facilities in Fort Saskatchewan, Alta. Photo courtesy Keyera Corp.

In June, Keyera Corp. announced a $5.15 billion deal to acquire the majority of Plains American Pipelines LLP’s Canadian natural gas liquids (NGL) business, creating a cross-Canada NGL corridor that includes a storage hub in Sarnia, Ontario.

The acquisition will connect NGLs from the growing Montney and Duvernay plays in Alberta and B.C. to markets in central Canada and the eastern U.S. seaboard.

“Having a Canadian source for natural gas would be our preference,” said Sarnia mayor Mike Bradley.

“We see Keyera’s acquisition as strengthening our region as an energy hub.”

1. Explained: Why Canadian oil is so important to the United States

Enbridge’s Cheecham Terminal near Fort McMurray, Alberta is a key oil storage hub that moves light and heavy crude along the Enbridge network. Photo courtesy Enbridge

The United States has become the world’s largest oil producer, but its reliance on oil imports from Canada has never been higher.

Many refineries in the United States are specifically designed to process heavy oil, primarily in the U.S. Midwest and U.S. Gulf Coast.

According to the Alberta Petroleum Marketing Commission, the top five U.S. refineries running the most Alberta crude are:

- Marathon Petroleum, Robinson, Illinois (100% Alberta crude)

- Exxon Mobil, Joliet, Illinois (96% Alberta crude)

- CHS Inc., Laurel, Montana (95% Alberta crude)

- Phillips 66, Billings, Montana (92% Alberta crude)

- Citgo, Lemont, Illinois (78% Alberta crude)

Alberta

Alberta project would be “the biggest carbon capture and storage project in the world”

Pathways Alliance CEO Kendall Dilling is interviewed at the World Petroleum Congress in Calgary, Monday, Sept. 18, 2023.THE CANADIAN PRESS/Jeff McIntosh

From Resource Works

Carbon capture gives biggest bang for carbon tax buck CCS much cheaper than fuel switching: report

Canada’s climate change strategy is now joined at the hip to a pipeline. Two pipelines, actually — one for oil, one for carbon dioxide.

The MOU signed between Ottawa and Alberta two weeks ago ties a new oil pipeline to the Pathways Alliance, which includes what has been billed as the largest carbon capture proposal in the world.

One cannot proceed without the other. It’s quite possible neither will proceed.

The timing for multi-billion dollar carbon capture projects in general may be off, given the retreat we are now seeing from industry and government on decarbonization, especially in the U.S., our biggest energy customer and competitor.

But if the public, industry and our governments still think getting Canada’s GHG emissions down is a priority, decarbonizing Alberta oil, gas and heavy industry through CCS promises to be the most cost-effective technology approach.

New modelling by Clean Prosperity, a climate policy organization, finds large-scale carbon capture gets the biggest bang for the carbon tax buck.

Which makes sense. If oil and gas production in Alberta is Canada’s single largest emitter of CO2 and methane, it stands to reason that methane abatement and sequestering CO2 from oil and gas production is where the biggest gains are to be had.

A number of CCS projects are already in operation in Alberta, including Shell’s Quest project, which captures about 1 million tonnes of CO2 annually from the Scotford upgrader.

What is CO2 worth?

Clean Prosperity estimates industrial carbon pricing of $130 to $150 per tonne in Alberta and CCS could result in $90 billion in investment and 70 megatons (MT) annually of GHG abatement or sequestration. The lion’s share of that would come from CCS.

To put that in perspective, 70 MT is 10% of Canada’s total GHG emissions (694 MT).

The report cautions that these estimates are “hypothetical” and gives no timelines.

All of the main policy tools recommended by Clean Prosperity to achieve these GHG reductions are contained in the Ottawa-Alberta MOU.

One important policy in the MOU includes enhanced oil recovery (EOR), in which CO2 is injected into older conventional oil wells to increase output. While this increases oil production, it also sequesters large amounts of CO2.

Under Trudeau era policies, EOR was excluded from federal CCS tax credits. The MOU extends credits and other incentives to EOR, which improves the value proposition for carbon capture.

Under the MOU, Alberta agrees to raise its industrial carbon pricing from the current $95 per tonne to a minimum of $130 per tonne under its TIER system (Technology Innovation and Emission Reduction).

The biggest bang for the buck

Using a price of $130 to $150 per tonne, Clean Prosperity looked at two main pathways to GHG reductions: fuel switching in the power sector and CCS.

Fuel switching would involve replacing natural gas power generation with renewables, nuclear power, renewable natural gas or hydrogen.

“We calculated that fuel switching is more expensive,” Brendan Frank, director of policy and strategy for Clean Prosperity, told me.

Achieving the same GHG reductions through fuel switching would require industrial carbon prices of $300 to $1,000 per tonne, Frank said.

Clean Prosperity looked at five big sectoral emitters: oil and gas extraction, chemical manufacturing, pipeline transportation, petroleum refining, and cement manufacturing.

“We find that CCUS represents the largest opportunity for meaningful, cost-effective emissions reductions across five sectors,” the report states.

Fuel switching requires higher carbon prices than CCUS.

Measures like energy efficiency and methane abatement are included in Clean Prosperity’s calculations, but again CCS takes the biggest bite out of Alberta’s GHGs.

“Efficiency and (methane) abatement are a portion of it, but it’s a fairly small slice,” Frank said. “The overwhelming majority of it is in carbon capture.”

From left, Alberta Minister of Energy Marg McCuaig-Boyd, Shell Canada President Lorraine Mitchelmore, CEO of Royal Dutch Shell Ben van Beurden, Marathon Oil Executive Brian Maynard, Shell ER Manager, Stephen Velthuizen, and British High Commissioner to Canada Howard Drake open the valve to the Quest carbon capture and storage facility in Fort Saskatchewan Alta, on Friday November 6, 2015. Quest is designed to capture and safely store more than one million tonnes of CO2 each year an equivalent to the emissions from about 250,000 cars. THE CANADIAN PRESS/Jason Franson

Credit where credit is due

Setting an industrial carbon price is one thing. Putting it into effect through a workable carbon credit market is another.

“A high headline price is meaningless without higher credit prices,” the report states.

“TIER credit prices have declined steadily since 2023 and traded below $20 per tonne as of November 2025. With credit prices this low, the $95 per tonne headline price has a negligible effect on investment decisions and carbon markets will not drive CCUS deployment or fuel switching.”

Clean Prosperity recommends a kind of government-backstopped insurance mechanism guaranteeing carbon credit prices, which could otherwise be vulnerable to political and market vagaries.

Specifically, it recommends carbon contracts for difference (CCfD).

“A straight-forward way to think about it is insurance,” Frank explains.

Carbon credit prices are vulnerable to risks, including “stroke-of-pen risks,” in which governments change or cancel price schedules. There are also market risks.

CCfDs are contractual agreements between the private sector and government that guarantees a specific credit value over a specified time period.

“The private actor basically has insurance that the credits they’ll generate, as a result of making whatever low-carbon investment they’re after, will get a certain amount of revenue,” Frank said. “That certainty is enough to, in our view, unlock a lot of these projects.”

From the perspective of Canadian CCS equipment manufacturers like Vancouver’s Svante, there is one policy piece still missing from the MOU: eligibility for the Clean Technology Manufacturing (CTM) Investment tax credit.

“Carbon capture was left out of that,” said Svante co-founder Brett Henkel said.

Svante recently built a major manufacturing plant in Burnaby for its carbon capture filters and machines, with many of its prospective customers expected to be in the U.S.

The $20 billion Pathways project could be a huge boon for Canadian companies like Svante and Calgary’s Entropy. But there is fear Canadian CCS equipment manufacturers could be shut out of the project.

“If the oil sands companies put out for a bid all this equipment that’s needed, it is highly likely that a lot of that equipment is sourced outside of Canada, because the support for Canadian manufacturing is not there,” Henkel said.

Henkel hopes to see CCS manufacturing added to the eligibility for the CTM investment tax credit.

“To really build this eco-system in Canada and to support the Pathways Alliance project, we need that amendment to happen.”

Resource Works News

-

Business2 days ago

Business2 days agoDisclosures reveal Minnesota politician’s husband’s companies surged thousands-fold amid Somali fraud crisis

-

Alberta2 days ago

Alberta2 days agoThe Canadian Energy Centre’s biggest stories of 2025

-

Business2 days ago

Business2 days agoResurfaced Video Shows How Somali Scammers Used Day Care Centers To Scam State

-

Business23 hours ago

Business23 hours agoThe Real Reason Canada’s Health Care System Is Failing

-

Business2 days ago

Business2 days agoMinneapolis day care filmed empty suddenly fills with kids

-

Business2 days ago

Business2 days agoOttawa Is Still Dodging The China Interference Threat

-

Business23 hours ago

Business23 hours agoFederal funds FROZEN after massive fraud uncovered: Trump cuts off Minnesota child care money

-

Opinion15 hours ago

Opinion15 hours agoGlobally, 2025 had one of the lowest annual death rates from extreme weather in history