Canadian Energy Centre

North America LNG project cost competitiveness

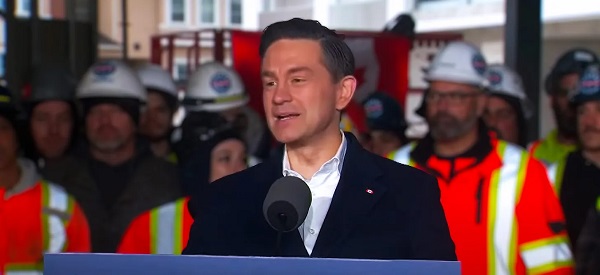

Construction workers look on at the FortisBC Tilbury LNG expansion project in Delta, B.C., Monday, Nov. 16, 2015. CP Images photo

From the Canadian Energy Centre

Lower costs for natural gas, shipping and liquefaction give Canada an edge in the emerging global LNG market

Worldwide concerns about energy security have put a renewed focus on the international liquefied natural gas (LNG) industry. The global demand for LNG is expected to increase over the next few decades.

Global demand growth will be driven primarily by Asian markets where the need for LNG is expected to increase from 277 million tonnes (MT) in 2025 to 509 MT by 2050 (see Figure 1). By 2050 the demand for LNG in Europe will be 83 MT and in Africa 20 MT. In South America too, demand will increase – from 13 MT in 2025 to 31 MT in 2050.

Source: Derived from Rystad Energy, Gas and LNG Markets Solution.

In North America (Canada, Mexico, and United States) a number of LNG projects that are either under construction or in the planning stages will benefit from the rise in global LNG demand.

North American LNG production is expected to grow from 112 MT in 2025 to over 255 MT by 2050 (see Figure 2). In Canada, the LNG projects under construction or in the planning stages include LNG Canada Phases 1 & 2, Woodfibre LNG, Cedar LNG, the Tilbury LNG expansion, and Ksi Lisims LNG. Canada’s LNG production is expected to grow from just 2 MT in 2025 to over 43 MT by 2050. In the United States production is projected to increase from 108 MT in 2025 to 210 MT in 2050.

Source: Derived from Rystad Energy, Gas and LNG Markets Solution.

This CEC Fact Sheet uses Rystad Energy’s Gas and LNG Markets Solution¹ to benchmark the cost competitiveness of LNG projects that are under construction and proposed in Canada compared to other LNG projects under construction and planned elsewhere in North America. (Note that the content of this report does not represent the views of Rystad Energy.)

The LNG cost competitiveness benchmarking analysis used the following performance metrics:

- LNG plant free-on-board (FOB) cost break-even;

- Total LNG plant cost (for delivery into Asia and Europe).

The objective of this LNG cost competitiveness benchmarking is to compare the competitiveness of Canadian LNG projects against those of major competitors in the United States and Mexico. The selection of other North American LNG facilities for the benchmark comparison with Canadian LNG projects (LNG Canada, the Tilbury LNG Expansion, Woodfibre LNG, Cedar LNG, and Ksi Lisims LNG) is based on the rationale that virtually all Canadian LNG plants are under construction or in the planning stage and that they compare well with other North American LNG plants that are also under construction or are being planned between 2023 and 2050. Further, to assess the cost competitiveness of the various LNG projects more accurately, we chose only North American LNG facilities with sufficient economic data to enable such a comparison. We compared the cost competitiveness of LNG coming from these other North American projects with LNG coming from Canada that is intended to be delivered to markets in Asia and Europe.

1. Rystad Energy is an independent energy research company providing data, analytics, and consultancy services to clients around the globe. Its Gas and LNG Markets Solution provides an overview of LNG markets worldwide. The Solution covers the entire value chain associated with gas and LNG production, country and sector-level demand, and LNG trade flows, infrastructure, economics, costs, and contracts through 2050. It allows for the evaluation of the entire LNG market infrastructure, including future planned projects, as well as the benchmarking of costs for LNG projects (Rystad Energy, 2024).

Comparison of LNG project FOB cost break-even (full cycle)

Figure 3 provides a comparison of the free-on-board (FOB) cost break-even for LNG facilities under construction or being planned in North America. FOB break-even costs include upstream and midstream costs for LNG excluding transportation costs (shipping) as seen from the current year. Break-even prices assume a discount rate of 10 percent and represent the point at which the net present value for an LNG project over a 20- to 30-year period becomes positive, including the payment of capital and operating costs, inclusive of taxes.

Among the selected group of North American LNG projects are Canadian LNG projects with an FOB break-even at the lower end of the range (US$7.18 per thousand cubic feet (kcf)) to those at the higher end (US$8.64 per thousand cubic feet (kcf)).

LNG projects in the United States tend to settle in the middle of the pack, with FOB break-even between US$6.44 per kcf and US$8.37 per kcf.

Mexico LNG projects have the widest variation in costs among the selected group of projects, ranging from US$6.94 per kcf to US$9.44 per kcf (see Figure 3).

Source: Derived from Rystad Energy, Gas and LNG Markets Solution.

Total costs by project for LNG delivery to Asia and Europe

The total cost by LNG plant includes FOB cost break-even, transportation costs, and the regasification tariff. Figure 4 compares total project costs for LNG destined for Asia from selected North American LNG facilities.

Canadian LNG projects are very cost competitive, and those with Asia as their intended market tend to cluster at the lower end of the scale. The costs vary by project, but range between US$8.10 per kcf and US$9.56 per kcf, making Canadian LNG projects among the lowest cost projects in North America.

The costs for Mexico’s LNG projects with Asia as the intended destination for their product tend to cluster in the middle of the pack. Costs among U.S. LNG facilities that plan to send their product to Asia tend to sit at the higher end of the scale, at between US$8.90 and US$10.80 per kcf.

Source: Derived from Rystad Energy, Gas and LNG Markets Solution.

Figure 5 compares total project costs for LNG to be delivered to Europe from select North American LNG facilities.

Costs from U.S. LNG facilities show the widest variation for this market at between US$7.48 per kcf and US$9.42 per kcf, but the majority of U.S. LNG facilities tend to cluster at the lower end of the cost scale, between US$7.48 per kcf and US$8.61 per kcf (see Figure 5).

Canadian projects that intend to deliver LNG to Europe show a variety of costs that tend to cluster at the middle to higher end of the spectrum, ranging from US$9.60 per kcf to and US$11.06 per kcf.

The costs of Mexico’s projects that are aimed at delivering LNG to Europe tend to cluster in the middle of the spectrum (US$9.11 per kcf to US$10.61 per kcf).

Source: Derived from Rystad Energy, Gas and LNG Markets Solution.

Conclusion

LNG markets are complex. Each project is unique and presents its own challenges. The future of Canadian LNG projects depends upon the overall demand and supply in the global LNG market. As the demand for LNG increases in the next decades, the world will be searching for energy security.

The lower liquefaction and shipping costs coupled with the lower cost of the natural gas itself in Western Canada translate into lower prices for Canadian LNG, particularly that destined for Asian markets. Those advantages will help make Canadian LNG very competitive and attractive to markets worldwide.

2025 Federal Election

Canada’s pipeline builders ready to get to work

From the Canadian Energy Centre

“We’re focusing on the opportunity that Canada has, perhaps even the obligation”

It was not a call he wanted to make.

In October 2017, Kevin O’Donnell, then chief financial officer of Nisku, Alta.-based Banister Pipelines, got final word that the $16-billion Energy East pipeline was cancelled.

It was his job to pass the news down the line to reach workers who were already in the field.

“We had a crew that was working along the current TC Energy line that was ready for conversion up in Thunder Bay,” said O’Donnell, who is now executive director of the Mississauga, Ont.-based Pipe Line Contractors Association of Canada (PLCAC).

“I took the call, and they said abandon right now. Button up and abandon right now.

“It was truly surreal. It’s tough to tell your foreman, who then tells their lead hands and then you inform the unions that those three or four or five million man-hours that you expected are not going to come to fruition,” he said.

Workers guide a piece of pipe along the Trans Mountain expansion route. Photograph courtesy Trans Mountain Corporation

“They’ve got to find lesser-paying jobs where they’re not honing their craft in the pipeline sector. You’re not making the money; you’re not getting the health and dental coverage that you were getting before.”

O’Donnell estimates that PLCAC represents about 500,000 workers across Canada through the unions it works with.

With the recent completion of the Trans Mountain expansion and Coastal GasLink pipelines – and no big projects like them coming on the books – many are once again out of a job, he said.

It’s frustrating given that this could be what he called a “golden age” for building major energy infrastructure in Canada.

Together, more than 62,000 people were hired to build the Trans Mountain expansion and Coastal GasLink projects, according to company reports.

O’Donnell is particularly interested in a project like Energy East, which would link oil produced in Alberta to consumers in Eastern and Atlantic Canada, then international markets in the offshore beyond.

“I think Energy East or something similar has to happen for millions of reasons,” he said.

“The world’s demanding it. We’ve got the craft [workers], we’ve got the iron ore and we’ve got the steel. We’re talking about a nation where the workers in every province could benefit. They’re ready to build it.”

The “Golden Weld” marked mechanical completion of construction of the Trans Mountain Expansion Project on April 11, 2024. Photo courtesy Trans Mountain Corporation

That eagerness is shared by the Progressive Contractors Association of Canada (PCA), which represents about 170 construction and maintenance employers across the country.

The PCA’s newly launched “Let’s Get Building” advocacy campaign urges all parties in the Canadian federal election run to focus on getting major projects built.

“We’re focusing on the opportunity that Canada has, perhaps even the obligation,” said PCA chief executive Paul de Jong.

“Most of the companies are quite busy irrespective of the pipeline issue right now. But looking at the long term, there’s predictability and long-term strategy that they see missing.”

Top of mind is Ottawa’s Impact Assessment Act (IAA), he said, the federal law that assesses major national projects like pipelines and highways.

In 2023, the Supreme Court of Canada found that the IAA broke the rules of the Canadian constitution.

The court found unconstitutional components including federal overreach into the decision of whether a project requires an impact assessment and whether a project gets final approval to proceed.

Ottawa amended the act in the spring of 2024, but Alberta’s government found the changes didn’t fix the issues and in November launched a new legal challenge against it.

“We’d like to see the next federal administration substantially revisit the Impact Assessment Act,” de Jong said.

“The sooner these nation-building projects get underway, the sooner Canadians reap the rewards through new trading partnerships, good jobs and a more stable economy.”

Canadian Energy Centre

First Nations in Manitoba pushing for LNG exports from Hudson’s Bay

From the Canadian Energy Centre

By Will Gibson

NeeStaNan project would use port location selected by Canadian government more than 100 years ago

Building a port on Hudson’s Bay to ship natural resources harvested across Western Canada to the world has been a long-held dream of Canadian politicians, starting with Sir Wilfred Laurier.

Since 1931, a small deepwater port has operated at Churchill, Manitoba, primarily shipping grain but more recently expanding handling of critical minerals and fertilizers.

A group of 11 First Nations in Manitoba plans to build an additional industrial terminal nearby at Port Nelson to ship liquefied natural gas (LNG) to Europe and potash to Brazil.

Robyn Lore, a director with project backer NeeStaNan, which is Cree for “all of us,” said it makes more sense to ship Canadian LNG to Europe from an Arctic port than it does to send Canadian natural gas all the way to the U.S. Gulf Coast to be exported as LNG to the same place – which is happening today.

“There is absolutely a business case for sending our LNG directly to European markets rather than sending our natural gas down to the Gulf Coast and having them liquefy it and ship it over,” Lore said. “It’s in Canada’s interest to do this.”

Over 100 years ago, the Port Nelson location at the south end of Hudson’s Bay on the Nelson River was the first to be considered for a Canadian Arctic port.

In 1912, a Port Nelson project was selected to proceed rather than a port at Churchill, about 280 kilometres north.

The Port Nelson site was earmarked by federal government engineers as the most cost-effective location for a terminal to ship Canadian resources overseas.

Construction started but was marred by building challenges due to violent winter storms that beached supply ships and badly damaged the dredge used to deepen the waters around the port.

By 1918, the project was abandoned.

In the 1920s, Prime Minister William Lyon MacKenzie King chose Churchill as the new location for a port on Hudson’s Bay, where it was built and continues to operate today between late July and early November when it is not iced in.

Lore sees using modern technology at Port Nelson including dredging or extending a floating wharf to overcome the challenges that stopped the project from proceeding more than a century ago.

He said natural gas could travel to the terminal through a 1,000-kilometre spur line off TC Energy’s Canadian Mainline by using Manitoba Hydro’s existing right of way.

A second option proposes shipping natural gas through Pembina Pipeline’s Alliance system to Regina, where it could be liquefied and shipped by rail to Port Nelson.

The original rail bed to Port Nelson still exists, and about 150 kilometers of track would have to be laid to reach the proposed site, Lore said.

“Our vision is for a rail line that can handle 150-car trains with loads of 120 tonnes per car running at 80 kilometers per hour. That’s doable on the line from Amery to Port Nelson. It makes the economics work for shippers,” said Lore.

Port Nelson could be used around the year because saltwater ice is easier to break through using modern icebreakers than freshwater ice that impacts Churchill between November and May.

Lore, however, is quick to quell the notion NeeStaNan is competing against the existing port.

“We want our project to proceed on its merits and collaborate with other ports for greater efficiency,” he said.

“It makes sense for Manitoba, and it makes sense for Canada, even more than it did for Laurier more than 100 years ago.”

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoBREAKING: THE FEDERAL BRIEF THAT SHOULD SINK CARNEY

-

2025 Federal Election2 days ago

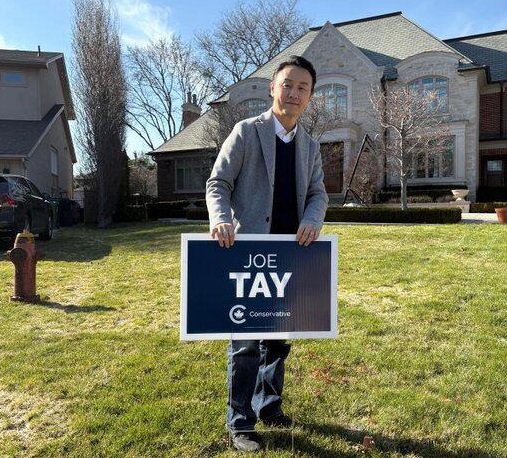

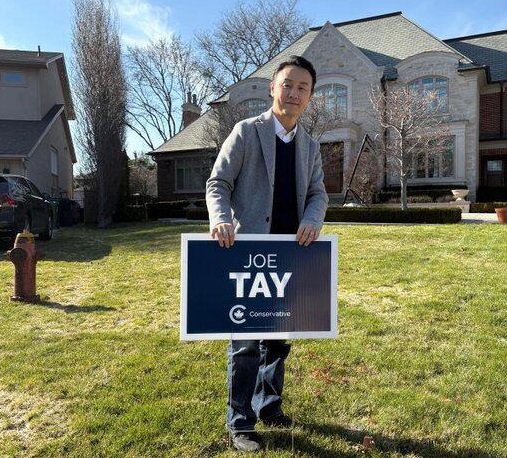

2025 Federal Election2 days agoCHINESE ELECTION THREAT WARNING: Conservative Candidate Joe Tay Paused Public Campaign

-

2025 Federal Election1 day ago

2025 Federal Election1 day agoMark Carney Wants You to Forget He Clearly Opposes the Development and Export of Canada’s Natural Resources

-

International1 day ago

International1 day agoPope Francis’ body on display at the Vatican until Friday

-

Business2 days ago

Business2 days agoHudson’s Bay Bid Raises Red Flags Over Foreign Influence

-

2025 Federal Election1 day ago

2025 Federal Election1 day agoCanada’s pipeline builders ready to get to work

-

2025 Federal Election16 hours ago

2025 Federal Election16 hours agoFormer WEF insider accuses Mark Carney of using fear tactics to usher globalism into Canada

-

International2 days ago

International2 days agoPope Francis’ funeral to take place Saturday