Automotive

New Analysis Shows Just How Bad Electric Trucks Are For Business

From the Daily Caller News Foundation

From the Daily Caller News Foundation

By WILL KESSLER

Converting America’s medium- and heavy-duty trucks to electric vehicles (EV) in accordance with goals from the Biden administration would add massive costs to commercial trucking, according to a new analysis released Wednesday.

The cost to switch over to light-duty EVs like a transit van would equate to a 5% increase in costs per year while switching over medium- and heavy-duty trucks would add up to 114% in costs per year to already struggling businesses, according to a report from transportation and logistics company Ryder Systems. The Biden administration, in an effort to facilitate a transition to EVs, finalized new emission standards in March that would require a huge number of heavy-duty vehicles to be electric or zero-emission by 2032 and has created a plan to roll out charging infrastructure across the country.

“There are specific applications where EV adoption makes sense today, but the use cases are still limited,” Karen Jones, executive vice president at Ryder, said in an accompanying press release. “Yet we’re facing regulations aimed at accelerating broader EV adoption when the technology and infrastructure are still developing. Until the gap in TCT for heavier-duty vehicles is narrowed or closed, we cannot expect many companies to make the transition, and, if required to convert in today’s market, we face more supply chain disruptions, transportation cost increases, and additional inflationary pressure.”

Due to the increase in costs for businesses, the potential inflationary impact on the entire economy per year is between 0.5% and 1%, according to the report. Inflation is already elevated, measuring 3.5% year-over-year in March, far from the Federal Reserve’s 2% target.

Increased expense projections differ by state, with class 8 heavy-duty trucks costing 94% more per year in California compared to traditional trucks, due largely to a 501% increase in equipment costs, while cost savings on fuel only amounted to 52%. In Georgia, costs would be 114% higher due to higher equipment costs, labor costs, a smaller payload capacity and more.

The EPA also recently finalized rules mandating that 67% of all light-duty vehicles sold after 2032 be electric or hybrid. Around $1 billion from the Inflation Reduction Act has already been designated to be used by subnational governments in the U.S. to replace some heavy-duty vehicles with EVs, like delivery trucks or school buses.

The Biden administration has also had trouble expanding EV charging infrastructure across the country, despite allotting $7.5 billion for chargers in 2021. Current charging infrastructure frequently has issues operating properly, adding to fears of “range anxiety,” where EV owners worry they will become stranded without a charger.

Automotive

Canadians’ Interest in Buying an EV Falls for Third Year in a Row

From Energy Now

Electric vehicle prices fell 7.8 per cent in the last quarter of 2024 year-over-year, according to the AutoTader price index

Fewer Canadians are considering buying an electric vehicle, marking the third year in a row interest has dropped despite lower EV prices, a survey from AutoTrader shows.

Forty-two per cent of survey respondents say they’re considering an EV as their next vehicle, down from 46 per cent last year. In 2022, 68 per cent said they would consider buying an EV.

Meanwhile, 29 per cent of respondents say they would exclusively consider buying an EV — a significant drop from 40 per cent last year.

The report, which surveyed 1,801 people on the AutoTrader website, shows drivers are concerned about reduced government incentives, a lack of infrastructure and long-term costs despite falling prices.

Electric vehicle prices fell 7.8 per cent in the last quarter of 2024 year-over-year, according to the AutoTader price index.

The survey, conducted between Feb. 13 and March 12, shows 68 per cent of non-EV owners say government incentives could influence their decision, while a little over half say incentives increase their confidence in buying an EV.

Automotive

Hyundai moves SUV production to U.S.

MxM News

MxM News

Quick Hit:

Hyundai is responding swiftly to 47th President Donald Trump’s newly implemented auto tariffs by shifting key vehicle production from Mexico to the U.S. The automaker, heavily reliant on the American market, has formed a specialized task force and committed billions to American manufacturing, highlighting how Trump’s America First economic policies are already impacting global business decisions.

Key Details:

-

Hyundai has created a tariffs task force and is relocating Tucson SUV production from Mexico to Alabama.

-

Despite a 25% tariff on car imports that began April 3, Hyundai reported a 2% gain in Q1 operating profit and maintained earnings guidance.

-

Hyundai and Kia derive one-third of their global sales from the U.S., where two-thirds of their vehicles are imported.

Diving Deeper:

In a direct response to President Trump’s decisive new tariffs on imported automobiles, Hyundai announced Thursday it has mobilized a specialized task force to mitigate the financial impact of the new trade policy and confirmed production shifts of one of its top-selling models to the United States. The move underscores the gravity of the new 25% import tax and the economic leverage wielded by a White House that is now unambiguously prioritizing American industry.

Starting with its popular Tucson SUV, Hyundai is transitioning some manufacturing from Mexico to its Alabama facility. Additional consideration is being given to relocating production away from Seoul for other U.S.-bound vehicles, signaling that the company is bracing for the long-term implications of Trump’s tariffs.

This move comes as the 25% import tax on vehicles went into effect April 3, with a matching tariff on auto parts scheduled to hit May 3. Hyundai, which generates a full third of its global revenue from American consumers, knows it can’t afford to delay action. Notably, U.S. retail sales for Hyundai jumped 11% last quarter, as car buyers rushed to purchase vehicles before prices inevitably climb due to the tariff.

Despite the trade policy, Hyundai reported a 2% uptick in first-quarter operating profit and reaffirmed its earnings projections, indicating confidence in its ability to adapt. Yet the company isn’t taking chances. Ahead of the tariffs, Hyundai stockpiled over three months of inventory in U.S. markets, hoping to blunt the initial shock of the increased import costs.

In a significant show of good faith and commitment to U.S. manufacturing, Hyundai last month pledged a massive $21 billion investment into its new Georgia plant. That announcement was made during a visit to the White House, just days before President Trump unveiled the auto tariff policy — a strategic alignment with a pro-growth, pro-America agenda.

Still, the challenges are substantial. The global auto industry depends on complex, multi-country supply chains, and analysts warn that tariffs will force production costs higher. Hyundai is holding the line on pricing for now, promising to keep current model prices stable through June 2. After that, however, price adjustments are on the table, potentially passing the burden to consumers.

South Korea, which remains one of the largest exporters of automobiles to the U.S., is not standing idle. A South Korean delegation is scheduled to meet with U.S. trade officials in Washington Thursday, marking the start of negotiations that could redefine the two nations’ trade dynamics.

President Trump’s actions represent a sharp pivot from the era of global corporatism that defined trade under the Obama-Biden administration. Hyundai’s swift response proves that when the U.S. government puts its market power to work, foreign companies will move mountains — or at least entire assembly lines — to stay in the game.

-

2025 Federal Election1 day ago

2025 Federal Election1 day agoTrump Has Driven Canadians Crazy. This Is How Crazy.

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoCarney’s Hidden Climate Finance Agenda

-

2025 Federal Election2 days ago

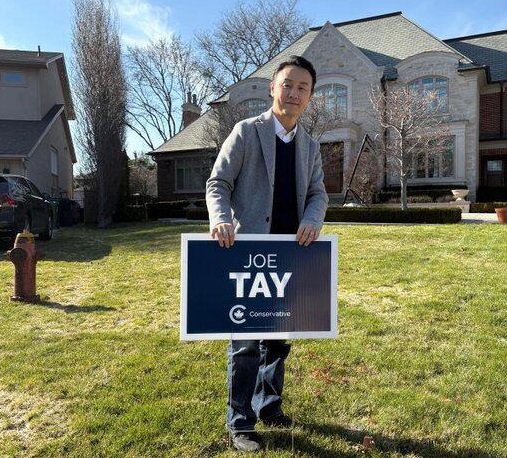

2025 Federal Election2 days agoThe Anhui Convergence: Chinese United Front Network Surfaces in Australian and Canadian Elections

-

2025 Federal Election2 days ago

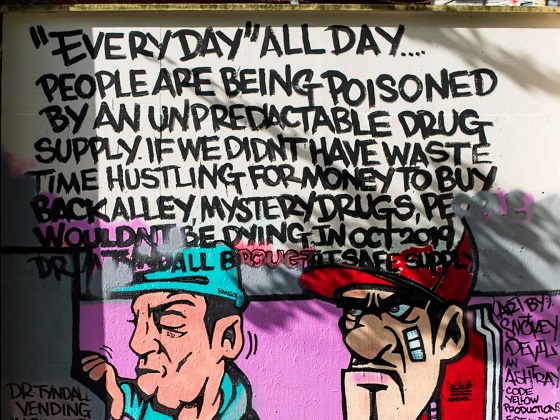

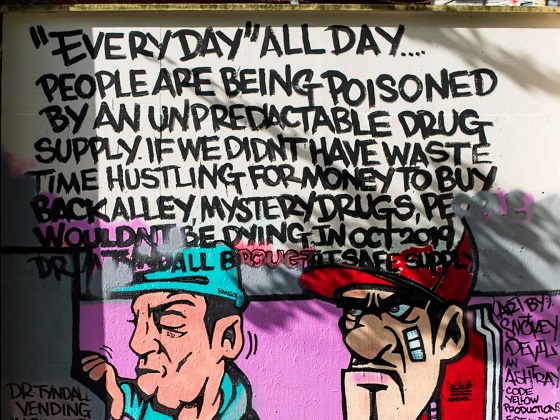

2025 Federal Election2 days agoStudy links B.C.’s drug policies to more overdoses, but researchers urge caution

-

Automotive22 hours ago

Automotive22 hours agoHyundai moves SUV production to U.S.

-

Entertainment1 day ago

Entertainment1 day agoPedro Pascal launches attack on J.K. Rowling over biological sex views

-

2025 Federal Election2 days ago

2025 Federal Election2 days agoWhen it comes to pipelines, Carney’s words flow both ways

-

2025 Federal Election18 hours ago

2025 Federal Election18 hours agoAs PM Poilievre would cancel summer holidays for MP’s so Ottawa can finally get back to work