Automotive

Electric vehicles facing uphill climb

From Resource Works

Ford shifts from EVs to gasoline trucks in Oakville due to declining demand and financial losses, challenging government EV targets.

In October 2020, the federal and Ontario governments announced with fanfare that they would each pour $295 million into helping Ford upgrade its assembly plant in Oakville to start making electric vehicles.

“The upgrade of the Ford plant will make Oakville into the company’s No 1. electric vehicle factory in North America,” we were told.

And Prime Minister Trudeau declared: “This is a win-win. . . . helping accelerate our transition to a low-carbon, clean-growth economy, which will help protect our environment, drive innovation, and create many good middle-class jobs.”

In April 2023, Ford announced it will spend $1.8 billion to retool its Oakville Assembly Complex, beginning in mid-2024, to build next-generation passenger electric vehicles in 2025.

Then the target date of 2025 becomes 2027.

And now, in July 2024, reality strikes: Ford confirmed that the Oakville plant would no longer produce electric three-row SUVs but would instead turn out larger, gasoline-powered versions of its flagship F-Series pickup truck.

The reason: a global slowdown in electric vehicle demand, with hesitant customers delaying plans to buy EVs, and many opting instead for hybrid-electric vehicles.

Ford, for one, said it will step up hybrid offerings and that by 2030 it expects to offer hybrid powertrains across its lineup of gas-powered vehicles. Ford has also delayed production of electric pickup trucks in Tennessee.

Ford now says its electric vehicle unit lost $1.3 billion USD in the first quarter alone. It sold 10,000 vehicles in that period, and thus lost about $132,000 US for every EV it sold.

General Motors also announced it would cut production of EVs, citing slowing demand.

As far as we know, Honda Canada is proceeding with a $15 billion plan to create Canada’s first comprehensive electric-vehicle supply chain, comprising four plants in Ontario. It includes Honda’s first EV assembly plant in Alliston, ON, which Honda said will produce up to 240,000 vehicles per year.

Flavio Volpe, president of the Automotive Parts Manufacturers Association, said the Ford decision is “not good news,” and he fears there will be similar announcements from other car companies.

And automotive industry analyst Robert Karwel says: “I would definitely not be surprised to see announcements from other companies.”

“People are getting payment fatigue right now generally, and EVs are more expensive,” said Karwel, a senior manager of J.D. Power’s Power Information Network. “The average car payment hit $900 a month in January.”

In the first quarter of this year, 46,744 light and medium-duty EVs were registered across Canada, 11.2% of the market share.

B.C. has long led Canada in the uptake of electric vehicles, and in May they made up 10.7% of light-duty vehicle sales.

But another factor weighing on consumers is B.C.’s recent reduction in rebates for electric vehicles.

B.C. reduced rebates to $3,000 for battery, fuel-cell and longer-range plug-in hybrid electric vehicles and $1,500 for shorter-range plug-in hybrid electric vehicles. The previous incentives ranged from $2,500 to $6,000, depending on the kind of car.

And now, only vehicles sold for under $55,000 qualify for the rebates. Previously, the maximum price was $77,000 to qualify. The federal rebate of $5,000 for qualifying vehicles, introduced on May 1, is still available.

If the slowdown in demand continues, it will only help power producers such as B.C. Hydro, which face staggering demand for power, for EVs and for industrial and clean-energy use.

The federal government requires at least 20% of new vehicles sold in Canada to be zero-emission vehicles (ZEVs) by 2026, at least 60% by 2030, and 100% by 2035. (ZEVs include battery electric vehicles and plug-in hybrid electric vehicles.)

Prime Minister Trudeau: “As a great Canadian once said, that is where the puck is going and that is where we’re going to be.”

B.C. is even more ambitious: It has set targets requiring 90% of all light-duty new vehicle sales to be zero-emission by 2030 and 100% by 2035.

That means B.C. needs substantially more power to cope with EVs — and will require even more than that to handle expected population growth and the province’s plans to electrify BC’s economy and push clean energy.

Now the Energy Futures Institute (EFI) calls in a new report for “a dramatic increase in domestic electricity production” in B.C., and cancellation of current plans to wind down some existing power-generation facilities.

EFI chair Barry Penner: “After years without new generation coming online, the long-awaited Site C dam is expected to start producing power by next year. Even if Site C was available last year or this year, it wouldn’t be enough to avoid having to import electricity from the United States and Alberta to keep our lights on.”

As for the federal target, the Public Policy Forum says Canada must build more electricity generation in the next 25 years than it has over the last century in order to support a net-zero emissions economy by 2050.

All in all, Canada’s electric vehicle transition could cost more than $300 billion by 2040 as the installation of charging infrastructure expands, upgrades to the electrical grid are made, and other changes take place, according to a report released by Natural Resources Canada.

Among other things, it says Canada needs to add 40,000 public charging ports per year on average between now and 2040. There now are around 32,000 public ports across the country, and roughly 11,000 were installed in 2023.

The Canadian Vehicle Manufacturers’ Association says lack of charging infrastructure is already deterring some would-be EV buyers. A lack of charging station availability was cited as a top concern by 72% of consumers, according to an Autotrader Canada survey conducted in March.

- Cornelius van Kooten, an economics professor and Canada Research Chair in Environmental Studies and Climate Change at the University of Victoria, said the federal timeline for electric vehicles “isn’t realistic or feasible.”

In a study for the free-enterprise Fraser Institute, he said that to meet the goal, Canada would need the equivalent of 10 big new hydro dams (or 13 large natural-gas power plants).

Quebec, for one, has already had to start limiting industrial expansion because it can’t fill all the power needs.

So you can but sigh when you hear of Quebec’s latest plan for electric vehicles: it is moving ahead with regulations that not only mandate EV sales but actually prohibit sales of any internal combustion engines — including plug-in hybrids, from January 1, 2035.

Automotive

Canada’s EV gamble is starting to backfire

Things have only gone from bad to worse for the global Electric Vehicle industry. And that’s a problem for Canada, because successive Liberal governments have done everything in their power to hitch our cart to that horse.

Earlier this month, the Trump Administration rolled back more Biden-era regulations that effectively served as a back-door EV mandate in the United States. These rules mandated that all passenger cars be able to travel at least 65.1 miles (and for light trucks, 45.2 miles) per gallon of gasoline or diesel, by the year 2031. Since no Internal Combustion Engine (ICE) vehicle could realistically conform to those standards, that would have essentially boxed them out of the market.

Trump’s rolling them back was a fulfillment of his campaign promise to end the Biden Administration’s stealth EV mandates. But it was also a simple recognition of the reality that EVs can’t compete on their own merits.

For proof of that, look no further than our second bit of bad news for EVs: Ford Motor Company has just announced a massive $19.5 billion write-down, almost entirely linked to its aggressive push into EVs. They’ve lost $13 billion on EVs in the past two years alone.

The company invested tens of billions on these go-carts, and lost their shirt when it turned out the market for them was miniscule.

Ford’s EV division president Andrew Frick explained, “Ford is following the customer. We are looking at the market as it is today, not just as everyone predicted it to be five years ago.”

Of course, five years ago, the market was assuming that government subsidies-plus-mandates would create a market for EVs at scale, which hasn’t happened.

As to what this portends for the market, the Wall Street Journal argued, “The company’s pivot from all-electric vehicles is a fresh sign that America’s roadways – after a push to remake them – will continue to look in the near future much like they do today, with a large number of gas-powered cars and trucks and growing use of hybrids.”

And that’s not just true in the U.S. Across the Atlantic, reports suggest the European Union is preparing to delay their own EV mandates to 2040. And the U.K.’s Labour government is considering postponing their own 2030 ICE vehicle ban to align with any EU change in policy.

It’s looking like fewer people around the world will be forced by their governments to buy EVs. Which means that fewer people will be buying EVs.

Now, that is a headache for Canada. Our leaders, at both the federal and provincial levels, have bet big on the success of EVs, investing billions in taxpayer dollars in the hopes of making Canada a major player in the global EV supply chain.

To bolster those investments, Ottawa introduced its Electric Vehicle mandate, requiring 100 per cent of new light-duty vehicle sales to be electric by 2035. This, despite the fact that EVs remain significantly more expensive than gas-and-diesel driven vehicles, they’re poorly suited to Canada’s vast distances and cold climate, and our charging infrastructure is wholly inadequate for a total transition to EVs.

But even if these things weren’t true, there still aren’t enough of us to make the government’s investment make sense. Their entire strategy depends on exporting to foreign markets that are rapidly cooling on EVs.

Collapsing demand south of the border – where the vast majority of the autos we build are sent – means that Canadian EVs will be left without buyers. And postponed (perhaps eventually canceled) mandates in Europe mean that we will be left without a fallback market.

Canadian industry voices are growing louder in their concern. Meanwhile, plants are already idling, scaling back production, or even closing, leaving workers out in the cold.

As GM Canada’s president, Kristian Aquilina, said when announcing her company’s cancellation of the BrightDrop Electric delivery van, “Quite simply, we just have not seen demand for these vehicles climb to the levels that we initially anticipated…. It’s simply a demand and a market-driven response.”

Prime Minister Mark Carney, while sharing much of the same environmental outlook as his predecessor, has already been compelled by economic realities to make a small adjustment – delaying the enforcement of the 2026 EV sales quotas by one year.

But a one-year pause doesn’t solve the problem. It kicks the can down the road.

Mr. Carney must now make a choice. He can double down on this troubled policy, continuing to throw good money after bad, endangering a lot of jobs in our automotive sector, while making transportation more expensive and less reliable for Canadians. Or he can change course: scrap the mandates, end the subsidies, and start putting people and prosperity ahead of ideology.

Here’s hoping he chooses the latter.

The writing is on the wall. Around the world, the forced transition to EVs is crashing into economic reality. If Canada doesn’t wake up soon, we’ll be left holding the bag.

Automotive

Ford’s EV Fiasco Fallout Hits Hard

From the Daily Caller News Foundation

I’ve written frequently here in recent years about the financial fiasco that has hit Ford Motor Company and other big U.S. carmakers who made the fateful decision to go in whole hog in 2021 to feed at the federal subsidy trough wrought on the U.S. economy by the Joe Biden autopen presidency. It was crony capitalism writ large, federal rent seeking on the grandest scale in U.S. history, and only now are the chickens coming home to roost.

Ford announced on Monday that it will be forced to take $19.5 billion in special charges as its management team embarks on a corporate reorganization in a desperate attempt to unwind the financial carnage caused by its failed strategies and investments in the electric vehicles space since 2022.

Cancelled is the Ford F-150 Lightning, the full-size electric pickup that few could afford and fewer wanted to buy, along with planned introductions of a second pricey pickup and fully electric vans and commercial vehicles. Ford will apparently keep making its costly Mustang Mach-E EV while adjusting the car’s features and price to try to make it more competitive. There will be a shift to making more hybrid models and introducing new lines of cheaper EVs and what the company calls “extended range electric vehicles,” or EREVs, which attach a gas-fueled generator to recharge the EV batteries while the car is being driven.

Dear Readers:

As a nonprofit, we are dependent on the generosity of our readers.

Please consider making a small donation of any amount here.

Thank you!

“The $50k, $60k, $70k EVs just weren’t selling; We’re following customers to where the market is,” Farley said. “We’re going to build up our whole lineup of hybrids. It’s gonna be better for the company’s profitability, shareholders and a lot of new American jobs. These really expensive $70k electric trucks, as much as I love the product, they didn’t make sense. But an EREV that goes 700 miles on a tank of gas, for 90% of the time is all-electric, that EREV is a better solution for a Lightning than the current all-electric Lightning.”

It all makes sense to Mr. Farley, but one wonders how much longer the company’s investors will tolerate his presence atop the corporate management pyramid if the company’s financial fortunes don’t turn around fast.

To Ford’s and Farley’s credit, the company has, unlike some of its competitors (GM, for example), been quite transparent in publicly revealing the massive losses it has accumulated in its EV projects since 2022. The company has reported its EV enterprise as a separate business unit called Model-E on its financial filings, enabling everyone to witness its somewhat amazing escalating EV-related losses since 2022:

• 2022 – Net loss of $2.2 billion

• 2023 – Net loss of $4.7 billion

• 2024 – Net loss of $5.1 billion

Add in the company’s $3.6 billion in losses recorded across the first three quarters of 2025, and you arrive at a total of $15.6 billion net losses on EV-related projects and processes in less than four calendar years. Add to that the financial carnage detailed in Monday’s announcement and the damage from the company’s financial electric boogaloo escalates to well above $30 billion with Q4 2025’s damage still to be added to the total.

Ford and Farley have benefited from the fact that the company’s lineup of gas-and-diesel powered cars have remained strongly profitable, resulting in overall corporate profits each year despite the huge EV-related losses. It is also fair to point out that all car companies were under heavy pressure from the Biden government to either produce battery electric vehicles or be penalized by onerous federal regulations.

Now, with the Trump administration rescinding Biden’s harsh mandates and canceling the absurdly unattainable fleet mileage requirements, Ford and other companies will be free to make cars Americans actually want to buy. Better late than never, as they say, but the financial fallout from it all is likely just beginning to be made public.

- David Blackmon is an energy writer and consultant based in Texas. He spent 40 years in the oil and gas business, where he specialized in public policy and communications.

-

International1 day ago

International1 day agoGeorgia county admits illegally certifying 315k ballots in 2020 presidential election

-

International1 day ago

International1 day agoCommunist China arrests hundreds of Christians just days before Christmas

-

Business23 hours ago

Business23 hours agoSome Of The Wackiest Things Featured In Rand Paul’s New Report Alleging $1,639,135,969,608 In Gov’t Waste

-

Alberta1 day ago

Alberta1 day agoCalgary’s new city council votes to ban foreign flags at government buildings

-

Energy13 hours ago

Energy13 hours agoThe Top News Stories That Shaped Canadian Energy in 2025 and Will Continue to Shape Canadian Energy in 2026

-

Business2 days ago

Business2 days agoWarning Canada: China’s Economic Miracle Was Built on Mass Displacement

-

International12 hours ago

International12 hours ago$2.6 million raised for man who wrestled shotgun from Bondi Beach terrorist

-

Alberta1 day ago

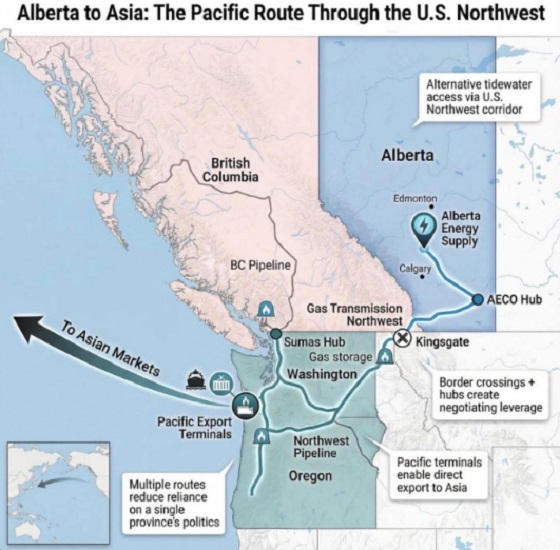

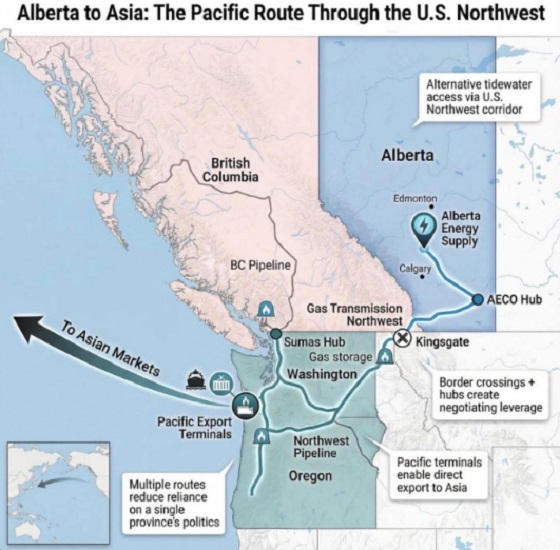

Alberta1 day agoWhat are the odds of a pipeline through the American Pacific Northwest