Fraser Institute

Trudeau and Ford should attach personal fortunes to EV corporate welfare

From the Fraser Institute

By Jason Clemens and Tegan Hill

Last week, with their latest tranche of corporate welfare for the electric vehicle (EV) sector, the Trudeau and Ford governments announced a $5.0 billion subsidy for Honda to help build an EV battery plant and ultimately manufacture EVs in Ontario. Here’s a challenge: if politicians in both governments truly believe these measures are in the public interest, they should tie their personal fortunes with the outcomes of these subsidies (a.k.a. corporate welfare).

One of the major challenges with corporate welfare is the horrendous economic incentives. The politicians and bureaucrats who distribute corporate welfare have no vested financial interest in the outcome of the program. Whether these programs are spectacularly successful (or more likely spectacular failures), the politicians and bureaucrats experience no direct financial gain or loss. Simply put, they’re investing taxpayer money, not their own.

Put differently, the discipline imposed on investors in private markets, such as the risk of losing money or even going out of business, is wholly absent in the government sector. Indeed, the history of corporate welfare in Canada, at both the federal and provincial levels, is rife with abject failures due in large measure to the absence of this investing discipline.

In the last 12 months in Ontario, automakers have been major beneficiaries of corporate welfare. The $5.0 billion for Honda is on top of $13.2 billion to Volkswagen and $15.0 billion to Stellantis. That equates to roughly $979 per taxpayer nationally for federal subsidies and an additional $1,372 for Ontario taxpayers. And these figures do not include the debt interest costs that will be incurred as both governments are borrowing money to finance the subsidies.

And there’s legitimate reason to be skeptical already of the potential success of these largescale industrial interventions by the federal (Liberal) and Ontario (Conservative) governments. EV sales in both Canada and the United States have not grown as expected by governments despite purchase subsidies. Disappointing EV sales have led several auto manufacturers including Toyota and Ford to scale-back their EV production plans.

There are also real concerns about the practical ability of EV manufacturers to secure required materials. Consider the minerals needed for EV batteries. According to a recent study, 388 new mines—including 50 lithium mines, 60 nickel mines and 17 cobalt mines—would be required by 2030 to meet EV adoption commitments by various governments. For perspective, there were a total of 340 metal mines operating across Canada and the U.S. in 2021. The massive task of finding, constructing and developing this level of new mines seems impractical and unattainable, meaning that EV plants being built now will struggle to secure needed inputs. Indeed, depending on the type of mine, it takes anywhere from six to 18 years to develop.

Which brings us back to the Trudeau and Ford governments. Given the economic incentive problems and practical challenges to a large-scale transition to EVs, would members of the Trudeau and Ford governments—including the prime minister and premier—want to attach a portion of their personal pensions to the success of these corporate welfare programs?

More specifically, assume an arrangement whereby those politicians would share the benefits of the program’s success but also share any losses through the value of their pensions. If the programs work as marketed, the politicians would enjoy higher valued pensions. But if the programs disappoint or even fail, their pensions would be reduced or even cancelled. Would these politicians still support billions in corporate handouts if their personal financial wellbeing was tied to the outcomes?

As the funding of private companies to develop the EV sector in Ontario continues with the support of taxpayer subsidies, Ontarians and all Canadians should consider the misalignment of economic incentives underpinning these subsidies and the practical challenges to the success of this industrial intervention.

Authors:

Business

Virtue-signalling devotion to reconciliation will not end well

From the Fraser Institute

By Bruce Pardy

In September, the British Columbia Supreme Court threw private property into turmoil. Aboriginal title in Richmond, a suburb of Vancouver, is “prior and senior” to fee simple interests, the court said. That means it trumps the property you have in your house, farm or factory. If the decision holds up on appeal, it would mean private property is not secure anywhere a claim for Aboriginal title is made out.

If you thought things couldn’t get worse, you thought wrong. On Dec. 5, the B.C. Court of Appeal delivered a different kind of upheaval. Gitxaala and Ehattesaht First Nations claimed that B.C.’s mining regime was unlawful because it allowed miners to register claims on Crown land without consulting with them. In a 2-to-1 split decision, the court agreed. The mining permitting regime is inconsistent with the United Nations Declaration on the Rights of Indigenous People (UNDRIP). And B.C. legislation, the court said, has made UNDRIP the law of B.C.

UNDRIP is a declaration of the United Nations General Assembly. It consists of pages and pages of Indigenous rights and entitlements. If UNDRIP is the law in B.C., then Indigenous peoples are entitled to everything—and to have other people pay for it. If you suspect that is an exaggeration, take a spin through UNDRIP for yourself.

Indigenous peoples, it says, “have the right to the lands, territories and resources which they have traditionally owned, occupied or otherwise used or acquired… to own, use, develop and control, as well as the right to “redress” for these lands, through either “restitution” or “just, fair and equitable compensation.” It says that states “shall consult and cooperate in good faith” in order to “obtain free and informed consent prior to the approval of any project affecting their lands or territories and other resources,” and that they have the right to “autonomy or self-government in matters relating to their internal and local affairs, as well as ways and means for financing their autonomous functions.”

The General Assembly adopted UNDRIP in 2007. At the time, Canada sensibly voted “no,” along with New Zealand, the United States and Australia. Eleven countries abstained. But in 2016, the newly elected Trudeau government reversed Canada’s objection.

UN General Assembly resolutions are not binding in international law. Nor are they enforceable in Canadian courts. But in 2019, NDP Premier John Horgan and his Attorney General David Eby, now the Premier, introduced Bill 41, the Declaration on the Rights of Indigenous Peoples Act (DRIPA). DRIPA proposed to require the B.C. government to “take all measures necessary to ensure the laws of British Columbia are consistent with the Declaration.” The B.C. Legislature unanimously passed the bill. (The Canadian Parliament passed a similar bill in 2021.)

Two years later, the legislature passed an amendment to the B.C. Interpretation Act. Eby, still B.C.’s Attorney General, sponsored the bill. The amendment read, “Every Act and regulation must be construed as being consistent with the Declaration.”

Eby has expressed dismay about the Court of Appeal decision. It “invites further and endless litigation,” he said. “It looked at the clear statements of intent in the legislature and the law, and yet reached dramatically different conclusions about what legislators did when we voted unanimously across party lines” to pass DRIPA. He has promised to amend the legislation.

These are crocodile tears. The majority judgment from the Court of Appeal is not a rogue decision from activist judges making things up and ignoring the law. Not this time, anyway. The court said that B.C. law must be construed as being consistent with UNDRIP—which is what Eby’s 2021 amendment to the Interpretation Act says.

In fact, Eby’s government has been doing everything in its power to champion Aboriginal interests. DRIPA is its mandate. It’s been making covert agreements with specific Aboriginal groups over specific territories. These agreements promise Aboriginal title and/or grant Aboriginal management rights over land use. In April 2024, an agreement with the Haida Council recognized Haida title and jurisdiction over Haida Gwaii, an archipelago off the B.C. coast formerly known as the Queen Charlotte Islands. Eby has said that the agreement is a template for what’s possible “in other places in British Columbia, and also in Canada.” He is putting title and control of B.C. into Aboriginal hands.

But it’s not just David Eby. The Richmond decision from the B.C. Supreme Court had nothing to do with B.C. legislation. It was a predictable result of years of Supreme Court of Canada (SCC) jurisprudence under Section 35 of the Constitution. That section guarantees “existing” Aboriginal and treaty rights as of 1982. But the SCC has since championed, evolved and enlarged those rights. Legislatures can fix their own statutes, but they cannot amend Section 35 or override judicial interpretation, even using the “notwithstanding clause.”

Meanwhile, on yet another track, Aboriginal rights are expanding under the Charter of Rights and Freedoms. On the same day as the B.C. Court of Appeal decision on UNDRIP, the Federal Court released two judgments. The federal government has an actionable duty to Aboriginal groups to provide housing and drinking water, the court declared. Taxpayer funded, of course.

One week later, at the other end of the country, the New Brunswick Court of Appeal weighed in. In a claim made by Wolastoqey First Nation for the western half of the province, the court said that Aboriginal title should not displace fee simple title of private owners. Yet it confirmed that a successful claim would require compensation in lieu of land. Private property owners or taxpayers, take your pick.

Like the proverb says, make yourself into a doormat and someone will walk all over you. Obsequious devotion to reconciliation has become a pathology of Canadian character. It won’t end well.

Business

The great policy challenge for governments in Canada in 2026

From the Fraser Institute

According to a recent study, living standards in Canada have declined over the past five years. And the country’s economic growth has been “ugly.” Crucially, all 10 provinces are experiencing this economic stagnation—there are no exceptions to Canada’s “ugly” growth record. In 2026, reversing this trend should be the top priority for the Carney government and provincial governments across the country.

Indeed, demographic and economic data across the country tell a remarkably similar story over the past five years. While there has been some overall economic growth in almost every province, in many cases provincial populations, fuelled by record-high levels of immigration, have grown almost as quickly. Although the total amount of economic production and income has increased from coast to coast, there are more people to divide that income between. Therefore, after we account for inflation and population growth, the data show Canadians are not better off than they were before.

Let’s dive into the numbers (adjusted for inflation) for each province. In British Columbia, the economy has grown by 13.7 per cent over the past five years but the population has grown by 11.0 per cent, which means the vast majority of the increase in the size of the economy is likely due to population growth—not improvements in productivity or living standards. In fact, per-person GDP, a key indicator of living standards, averaged only 0.5 per cent per year over the last five years, which is a miserable result by historic standards.

A similar story holds in other provinces. Prince Edward Island, Nova Scotia, Quebec and Saskatchewan all experienced some economic growth over the past five years but their populations grew at almost exactly the same rate. As a result, living standards have barely budged. In the remaining provinces (Newfoundland and Labrador, New Brunswick, Ontario, Manitoba and Alberta), population growth has outstripped economic growth, which means that even though the economy grew, living standards actually declined.

This coast-to-coast stagnation of living standards is unique in Canadian history. Historically, there’s usually variation in economic performance across the country—when one region struggles, better performance elsewhere helps drive national economic growth. For example, in the early 2010s while the Ontario and Quebec economies recovered slowly from the 2008/09 recession, Alberta and other resource-rich provinces experienced much stronger growth. Over the past five years, however, there has not been a “good news” story anywhere in the country when it comes to per-person economic growth and living standards.

In reality, Canada’s recent record-high levels of immigration and population growth have helped mask the country’s economic weakness. With more people to buy and sell goods and services, the overall economy is growing but living standards have barely budged. To craft policies to help raise living standards for Canadian families, policymakers in Ottawa and every provincial capital should remove regulatory barriers, reduce taxes and responsibly manage government finances. This is the great policy challenge for governments across the country in 2026 and beyond.

-

International2 days ago

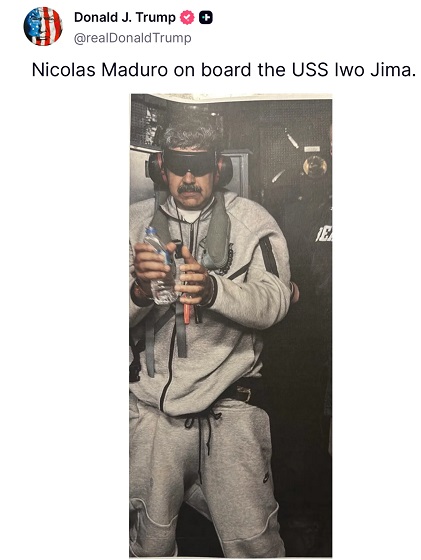

International2 days ago“Captured and flown out”: Trump announces dramatic capture of Maduro

-

International2 days ago

International2 days agoTrump Says U.S. Strike Captured Nicolás Maduro and Wife Cilia Flores; Bondi Says Couple Possessed Machine Guns

-

Energy2 days ago

Energy2 days agoThe U.S. Just Removed a Dictator and Canada is Collateral Damage

-

International2 days ago

International2 days agoUS Justice Department Accusing Maduro’s Inner Circle of a Narco-State Conspiracy

-

Business2 days ago

Business2 days agoVacant Somali Daycares In Viral Videos Are Also Linked To $300 Million ‘Feeding Our Future’ Fraud

-

Haultain Research1 day ago

Haultain Research1 day agoTrying to Defend Maduro’s Legitimacy

-

International2 days ago

International2 days agoU.S. Claims Western Hemispheric Domination, Denies Russia Security Interests On Its Own Border

-

Daily Caller1 day ago

Daily Caller1 day agoTrump Says US Going To Run Venezuela After Nabbing Maduro