Energy

173 day long disaster in India ended by Piston Well Services of Red Deer

Burning since June 9, a well blowout at Baghjan, India had foiled all who were tasked with somehow stopping the flames. Oil India Limited (OIL) tried regional companies and then it reached out internationally. Now one was able to fix this well blowout until they called in Piston Well Services Inc. The Red Deer based company was able to kill the well within days.

From the LinkedIn account of Piston Well Services Inc.

Alert Disaster Control (ALERT), with their well intervention service partner, Piston Well Services, have completed the critical well killing operation in Assam, India.

Piston Well Services mobilized a 142K Snubbing/Hydraulic Workover Unit and specialists to India to assist ALERT in the final phase of the well kill operation. Oil India Limited. officially designated the well as ‘killed’ on November 15 at 1400 hrs local time.

ALERT and Piston Well Services thank everyone that contributed and persevered through the unprecedented logistical challenges to support the operations. Oil India Limited’s commitment to the successful conclusion of the operations, will continue to support the local community and ensure the ongoing protection of the sensitive adjoining wetland areas.

#canadianenergy #albertaenergy #teampiston

News Video from RepublicWorld.com

The good news comes in the evening

OIL tweeted at 5.35 pm on Sunday: “Baghjan blowout well successfully killed: The well has been killed with brine solution & under control now. Fire has been doused completely. There is no pressure in the well now & the same will be observed for 24 hours to check if there is any amount of gas migration & pressure build up.”

The way ahead

What is snubbing unit and the process?

Baghjan gas well No 5 — India’s longest well on fire

Business

Virtue-signalling devotion to reconciliation will not end well

From the Fraser Institute

By Bruce Pardy

In September, the British Columbia Supreme Court threw private property into turmoil. Aboriginal title in Richmond, a suburb of Vancouver, is “prior and senior” to fee simple interests, the court said. That means it trumps the property you have in your house, farm or factory. If the decision holds up on appeal, it would mean private property is not secure anywhere a claim for Aboriginal title is made out.

If you thought things couldn’t get worse, you thought wrong. On Dec. 5, the B.C. Court of Appeal delivered a different kind of upheaval. Gitxaala and Ehattesaht First Nations claimed that B.C.’s mining regime was unlawful because it allowed miners to register claims on Crown land without consulting with them. In a 2-to-1 split decision, the court agreed. The mining permitting regime is inconsistent with the United Nations Declaration on the Rights of Indigenous People (UNDRIP). And B.C. legislation, the court said, has made UNDRIP the law of B.C.

UNDRIP is a declaration of the United Nations General Assembly. It consists of pages and pages of Indigenous rights and entitlements. If UNDRIP is the law in B.C., then Indigenous peoples are entitled to everything—and to have other people pay for it. If you suspect that is an exaggeration, take a spin through UNDRIP for yourself.

Indigenous peoples, it says, “have the right to the lands, territories and resources which they have traditionally owned, occupied or otherwise used or acquired… to own, use, develop and control, as well as the right to “redress” for these lands, through either “restitution” or “just, fair and equitable compensation.” It says that states “shall consult and cooperate in good faith” in order to “obtain free and informed consent prior to the approval of any project affecting their lands or territories and other resources,” and that they have the right to “autonomy or self-government in matters relating to their internal and local affairs, as well as ways and means for financing their autonomous functions.”

The General Assembly adopted UNDRIP in 2007. At the time, Canada sensibly voted “no,” along with New Zealand, the United States and Australia. Eleven countries abstained. But in 2016, the newly elected Trudeau government reversed Canada’s objection.

UN General Assembly resolutions are not binding in international law. Nor are they enforceable in Canadian courts. But in 2019, NDP Premier John Horgan and his Attorney General David Eby, now the Premier, introduced Bill 41, the Declaration on the Rights of Indigenous Peoples Act (DRIPA). DRIPA proposed to require the B.C. government to “take all measures necessary to ensure the laws of British Columbia are consistent with the Declaration.” The B.C. Legislature unanimously passed the bill. (The Canadian Parliament passed a similar bill in 2021.)

Two years later, the legislature passed an amendment to the B.C. Interpretation Act. Eby, still B.C.’s Attorney General, sponsored the bill. The amendment read, “Every Act and regulation must be construed as being consistent with the Declaration.”

Eby has expressed dismay about the Court of Appeal decision. It “invites further and endless litigation,” he said. “It looked at the clear statements of intent in the legislature and the law, and yet reached dramatically different conclusions about what legislators did when we voted unanimously across party lines” to pass DRIPA. He has promised to amend the legislation.

These are crocodile tears. The majority judgment from the Court of Appeal is not a rogue decision from activist judges making things up and ignoring the law. Not this time, anyway. The court said that B.C. law must be construed as being consistent with UNDRIP—which is what Eby’s 2021 amendment to the Interpretation Act says.

In fact, Eby’s government has been doing everything in its power to champion Aboriginal interests. DRIPA is its mandate. It’s been making covert agreements with specific Aboriginal groups over specific territories. These agreements promise Aboriginal title and/or grant Aboriginal management rights over land use. In April 2024, an agreement with the Haida Council recognized Haida title and jurisdiction over Haida Gwaii, an archipelago off the B.C. coast formerly known as the Queen Charlotte Islands. Eby has said that the agreement is a template for what’s possible “in other places in British Columbia, and also in Canada.” He is putting title and control of B.C. into Aboriginal hands.

But it’s not just David Eby. The Richmond decision from the B.C. Supreme Court had nothing to do with B.C. legislation. It was a predictable result of years of Supreme Court of Canada (SCC) jurisprudence under Section 35 of the Constitution. That section guarantees “existing” Aboriginal and treaty rights as of 1982. But the SCC has since championed, evolved and enlarged those rights. Legislatures can fix their own statutes, but they cannot amend Section 35 or override judicial interpretation, even using the “notwithstanding clause.”

Meanwhile, on yet another track, Aboriginal rights are expanding under the Charter of Rights and Freedoms. On the same day as the B.C. Court of Appeal decision on UNDRIP, the Federal Court released two judgments. The federal government has an actionable duty to Aboriginal groups to provide housing and drinking water, the court declared. Taxpayer funded, of course.

One week later, at the other end of the country, the New Brunswick Court of Appeal weighed in. In a claim made by Wolastoqey First Nation for the western half of the province, the court said that Aboriginal title should not displace fee simple title of private owners. Yet it confirmed that a successful claim would require compensation in lieu of land. Private property owners or taxpayers, take your pick.

Like the proverb says, make yourself into a doormat and someone will walk all over you. Obsequious devotion to reconciliation has become a pathology of Canadian character. It won’t end well.

Energy

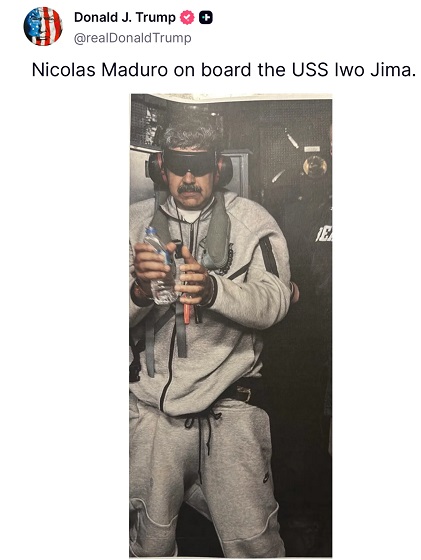

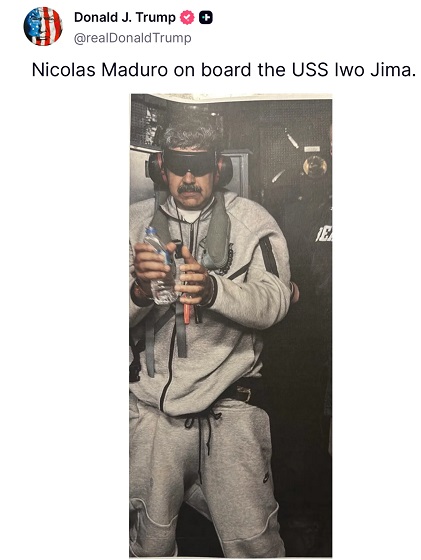

The U.S. Just Removed a Dictator and Canada is Collateral Damage

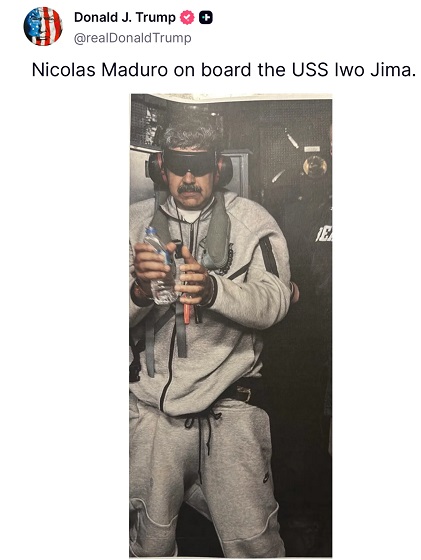

Early this morning, the United States says it carried out a ground raid supported by air strikes inside Venezuela, reportedly involving elite U.S. forces, including Delta Force, and removed Venezuelan President Nicolás Maduro and his wife Cilia Flores from the country.

President Donald Trump confirmed the operation publicly and stated that the United States intends to “run Venezuela” during a transition period, explicitly including control over the country’s oil sector. That single statement should alarm Canada far more than any diplomatic condemnation ever could.

Kelsi Sheren is a reader-supported publication.

To receive new posts and support my work, consider becoming a free or paid subscriber.

While this move may be justified on moral or strategic grounds for the U.S., it is unequivocally bad news for Canada, really really bad. Canada’s energy position just weakened significantly and now Canada’s leverage with the United States has always rested on one simple fact: the U.S. needed Canadian oil.

Not liked it. Needed it.

Canada became Washington’s largest and most reliable foreign energy supplier not because it was cheap, fast, or efficient but because alternatives were unstable, sanctioned, or politically toxic. Venezuela was one of those alternatives.

It isn’t anymore.

If the U.S. succeeds in stabilizing Venezuelan oil production under its influence, Canada loses something it cannot easily replace and wish it did sooner, strategic indispensability. When your biggest customer gains options, your negotiating power not only shrinks, it completely disappears.

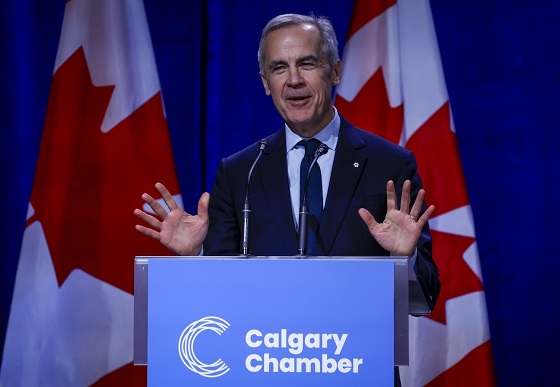

Venezuelan crude is largely heavy oil, the same category as much of Canada’s oil sands production. Many U.S. refineries, especially along the Gulf Coast, are designed to process heavy crude. For years, sanctions and mismanagement kept Venezuelan barrels off the market. Canadian heavy helped fill that gap. That advantage just cracked open. If Venezuelan supply re-enters global markets under U.S. oversight, Canadian oil faces more competition, downward pressure on prices, wider discounts for heavy crude and reduced urgency for new Canadian infrastructure. Urgency that Mark Carney refused to see was needed.

Canada’s oil is already expensive to extract and transport. It is already burdened by regulatory delays, pipeline bottlenecks, and political hostility at home. Now it faces a rival with larger reserves, lower production costs, shorter shipping routes and U.S. strategic backing

That is not a fair fight, but the liberals put us in this position and only have themselves to blame. Ottawa officially has no cards left to play. Canada’s response options are beyond limited and that’s the real problem.

Ottawa cannot meaningfully condemn the U.S. without risking trade and defence relations. It cannot influence Venezuelan reconstruction. It cannot outcompete Venezuelan oil on cost and it has spent years undermining its own energy sector in the name of climate virtue signalling. This is just the snake eating it’s tail and now realizing its proper fucked.

Canada is watching a major shift in global energy power from the sidelines, with no leverage and no contingency plan. This is the cost of mistaking morality for strategy. This is the cost of an ego gone unchecked.

Canada likes to tell itself that being stable, ethical, and predictable guarantees relevance. It doesn’t, Canada isn’t even in the game anymore it just hasn’t realized it. It only works when your partner has no better options.

The U.S. did not remove a communist dictator in Venezuela to protect Canadian interests. It did it to secure American interests energy, influence, and control. Thats what a real leader does, puts it’s country and it’s citizens first.

Canada’s reliability is now a nice bonus, not a necessity. That shift will show up quietly in trade negotiations, in infrastructure decisions and how quickly Canadian concerns get brushed aside. No dramatic break. Just less attention. Less urgency. Less patience and soon enough Canada won’t be invited to the table to even begin the conversation. Canada has just been down graded to the kids table.

This moment didn’t begin today. It began when Canada failed to build pipelines, ego drove away energy investment, allowed its regulatory system to become a chokehold and treated its largest export sector as an embarrassment.

While Ottawa debated optics, the U.S. planned for contingencies. Today was one of them.

The removal of a communist dictator in Venezuela may be a massive victory for it’s citizen and a strategic win for the United States but for Canada, it is a warning shot. Canada just became more optional in a world that punishes irrelevance quickly and quietly.

Being polite won’t save us. Being virtuous won’t save us.

Only being necessary ever did and today, Canada no longer became necessary.

KELSI SHEREN

– – – – – – – – – – – –

One Time Donation! – Paypal – https://paypal.me/

Buy me a coffee! – https://buymeacoffee.com/

Let’s connect!

Youtube – https://www.youtube.com/@

Instagram: https://www.instagram.com/

Substack: https://substack.com/@

TikTok – https://x.com/KelsiBurns

-

International1 day ago

International1 day ago“Captured and flown out”: Trump announces dramatic capture of Maduro

-

International1 day ago

International1 day agoTrump Says U.S. Strike Captured Nicolás Maduro and Wife Cilia Flores; Bondi Says Couple Possessed Machine Guns

-

Energy1 day ago

Energy1 day agoThe U.S. Just Removed a Dictator and Canada is Collateral Damage

-

International1 day ago

International1 day agoUS Justice Department Accusing Maduro’s Inner Circle of a Narco-State Conspiracy

-

Haultain Research1 day ago

Haultain Research1 day agoTrying to Defend Maduro’s Legitimacy

-

Business1 day ago

Business1 day agoVacant Somali Daycares In Viral Videos Are Also Linked To $300 Million ‘Feeding Our Future’ Fraud

-

Daily Caller18 hours ago

Daily Caller18 hours agoTrump Says US Going To Run Venezuela After Nabbing Maduro

-

International1 day ago

International1 day agoU.S. Claims Western Hemispheric Domination, Denies Russia Security Interests On Its Own Border